In accordance with a sampling plan the containers from each day's production have to be checked to make sure the seals are correct and undamaged. To do this the seams and cross seams have to be examined with suitable equipment.

Smoking must take place in a separate room or an area separated from the re>t of production. Ventilation is necessary if smoke or exhaust heat from smoke generation penetrates the other rooms in which fishery products are handled, processed or stored. The materials used for smoke generation must be stored outside the smoking room and used in such a way as to rule out any contamination of the fishery products. Wood which has been treated with paint, varnish, glue or other chemical preservatives is not permitted for use in smoke generation.

The storage of wood chips directly within the production area is not permitted by the Hygiene Directive since h is impossible to rule out negative impacts on the ready smoked product.

Smoker with insufficient ventilation; smoke penetrates the other production rooms.

If the smoking process also serves to kill parasites con temperature of the fisher; products has to be at icas +60°C.

If, after smoking, the fisher products are not destined foimmediate further processing, have to be cooled to the temperature required for the attendance of their tradability while preventing any loss in quality. Only then are they ready for packaging. As a rule a separate chilling room will be necessary for the ready smoked products. Too slow cooling under unhygienic condition-(air germ content) leads to termination and percepoble germ multiplication compared with the previously low-germ smoked product.

In the case of salting, too, a separate room is necessary or area which is at a suffiant distance from other processing activities.

The table salt used during the processing of fishery products must be clean and stored in such a way as to prevent contamination.

The containers, work materials and work areas used have to be cleaned prior to salting. Design and materials must be such that the fishery products are protected from contamination

during the salting process.

Drinking water only as understood by Directive 0/778/EWG is to be used for ooking crustaceans and mollusks. In they are cooked on board the fishing vessel, clean sea water can be used. After cooking, crustaceans and molluscs have to be cooled as quickly as possible to the temperature of melting ice (0°C). During this process they have to be protected from negative impacts, in particular from the sun.

Peeling the cooked crustaceans has to take place under perfect hygiene conditions. In the case of hand-peeling the workers have to wash their hands carefully and all work surfaces have to be thoroughly cleaned.

In the case of machine-peeling the machines have to be cleaned at short intervals and disinfected at the end of every working day.

Shrimp peeling machine(Kocken)

After the shell has been removed the crustacean meat has to be frozen immediately or stored chiiled in special rooms to avoid the development of pathogens. Cross-contamination with uncooked products must be avoided.

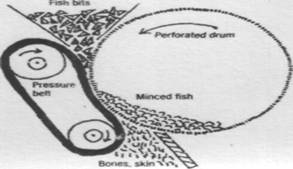

If during the production of minced fish meat the bones are removed by hand this has to be done immediately after cutting. Gut remains and guts are hot to be used. !f the whole fish is being used it-has tri" be gutted and washed beforehand. The machines used have to be cleaned frequently, at least every two hours. The resulting minced fish meat has to be frozen as quickly as possible or mixed into products which are to be frozen or preserved in some other way.

Working method of a bone separator

Метод работы отделителя костей.

During production and prior to marketing, fish and fishery products have to undergo visual testing in order to establish the presence of, and remove, visible parasites. Fish which are obviously infested with parasites and fish pieces which have been removed for this reason must not be marketed for human consumption.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.