Generally

(fig. 4.1, c) the distance from the surface of

the cathode up to the point, where electrons change the direction of movement

dt

is more than

thickness of dark cathode space

ds, that is an essential

feature of the magnetron sputtering mechanism, because the most effective

ionization of working gas is in this site of trajectory of electron movement.

For magnetron sputtering systems with the flat cathode

dt

usually

consider equal rд

[20, 54] and

determine it under the formula (4.5) (at

![]() , equal to the general energy

obtained by it up to the point of turn). When the size

dt

becomes more

than ds, that usually takes place

in sputtering

systems, the

size

, equal to the general energy

obtained by it up to the point of turn). When the size

dt

becomes more

than ds, that usually takes place

in sputtering

systems, the

size ![]() becomes equal to the potential drop

in the dark cathode space (approximately equal to the size of a discharge

potential) and dt

it can be

estimated easily. The mechanism of magnetron sputtering is realized in a

non-uniform magnetic field which lines have significant curvature (fig. 4.1, d). In the magnetic field of

such form having gradients

perpendicular

becomes equal to the potential drop

in the dark cathode space (approximately equal to the size of a discharge

potential) and dt

it can be

estimated easily. The mechanism of magnetron sputtering is realized in a

non-uniform magnetic field which lines have significant curvature (fig. 4.1, d). In the magnetic field of

such form having gradients

perpendicular

![]() and parallel

and parallel

![]() with the cathode, electrons

drift already

in the direction

with the cathode, electrons

drift already

in the direction ![]() which is perpendicular as

which is perpendicular as![]() ,

and

,

and

![]() . Thus the general electron drift at

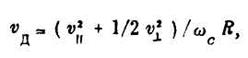

field lines of the circular form occurs to speedv

[20, 54]:

. Thus the general electron drift at

field lines of the circular form occurs to speedv

[20, 54]:

(4.7)

(4.7)

WhereR

- the radius

of curvature of a field, and the perpendicular component of their speed depends

on sizes ![]() and

and

![]() :

:

![]() (4.8)

(4.8)

At the

gradient of the field ![]() parallel with

parallel with

![]() in area, which is close to

the cathode surface where lines of a field enter into the cathode, electrons, moving on the trajectory

(fig. 1.1, d),

aspire to

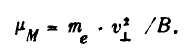

keep their magnetic moment μМ

[54]:

in area, which is close to

the cathode surface where lines of a field enter into the cathode, electrons, moving on the trajectory

(fig. 1.1, d),

aspire to

keep their magnetic moment μМ

[54]:

(4.9)

(4.9)

Power electrons in magnetron sputtering systems with the flat cathode move on the certain trajectories (fig. 4.1, е). Electrons, emitted by the cathode feel simultaneously action of forceF in the direction of the electric field, forcing them to move in the direction, perpendicular to the cathode, and centripetal forcef which forces them to move on circular trajectories around the lines of the magnetic field. Thus, electron goes on the curvilinear trajectory bringing it back to the surface of the cathode. Near this surface it slows down the movement until it will start to move in the initial direction (fig. 4.1, е). At the normal mode of dispersion (cathode potential ~500 V and the size of the magnetic field ~ 0,03 Tl) electron can leave the surface of the cathode at the distance up to 0,25 sm and can be displaced along the cathode each time at the distance up to 0,5 sm [54].

As a rule, the great number of electrons don’t leave the zone of run until they will not collide with atoms of working gas (only insignificant quantity can get the surface of the cathode in the bottom part of the trajectory of movement). The result of such complex electron movement is high-intensity ionization in the zone of their run and formation of dense plasma. The most part of ionizing collisions occurs inside and in immediate proximity from " the magnetic tunnel ", i.e. in the zone, where lines of the magnetic field are parallel with the cathode. Thus positive ions move from the zone of plasma mainly in the field of low electric fieldЕ(Е = ΔF, where F - potential of plasma), rotating around the lines of the magnetic field in plane, perpendicular to the cathode surface. Trajectories of movement of ions also change under action of the magnetic field, but, owing to the big weight of ions (see tab. 4.1) the radius of their rotation is more, than at the radius of electron rotation, and trajectories of ions have considerably smaller curvature, so practically they enter into the cathode space normally to the surface of the cathode. Being accelerated in the cathode space under action of the electric field up to energies of discharge potential, ions of working gas bombard the cathode - target practically normal to its surface, as well as in case of usual diode dispersions. Thus energy of ions suffices both for dispersion of the target surface, and for enough formation of secondary electrons.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.