![]() (5.4)

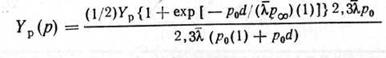

(5.4)

Whereλр ∞(1) - average length of free path of the sprayed atoms at р=1 Pa and Т>> C(C - Sutherland's constant).

Let's enter concept of average length of the directed path at individual pressure of gas LK(1) =LKp which according to (5.4) can be determined as

![]() (5.5)

(5.5)

In tab. (5.5) values Lк designed on the formula (1) for lines of metals are resulted at dispersion by their ions of argon with energy 0,6 - 4 keV.

Table 5.5

Average length of the directed path of the sprayed atoms

|

Sprayed material |

Ti |

Cu |

Ni |

Fe |

Mo |

Au |

Ta |

W |

Pt |

|

LK(1), 10-2 Pa×m |

1,41 |

2,13 |

2,33 |

2,54 |

3,58 |

3,55 |

5,80 |

5,95 |

6,07 |

In view of the initial direction of movement of the sprayed atoms in gas dependence of the dispersion coefficient on product p0d can be written down at p0d <LК (1) as

Yp(p)=Yp, (5.6)

and at p0d> LК as

Yp(p)=Yp2,3λр0(1)/[2,3λр0(1)+р0d-LK(1)]. (5.7)

Pressure of gas at which process of returning of the sprayed material on a target begins as a result of outdiffusion, is determined by the formula

po=LK(l)/d (5.8)

Apparently on fig. 5.14 (curves3), dependencesYp=f (pod) for copper and the nickel, designed by the formula (5.7), describe experimental data, than the dependences designed by the formula (5.3) much more precisely. (5.8) values found on the formula pod, at which return diffusion begins (the beginning of reduction of the dispersion coefficient on fig. 5.14), will be coordinated well to experiment and can be used at a choice of optimum technological modes of dispersion and etching of materials. Sharper reduction of the dispersion coefficient with growth pod on (5.7) dependences designed by the formula in comparison with experimental in the field of outdiffusion is connected to an assumption about transfer of the maximal share of energy Е from the sprayed atoms to atoms of gas and with approximation of distribution of the sprayed atoms on energies Ер.

At mа <mg the basic process determining returning of particles on the target in area pod<.LK (1) is outdispersion. Dependence of the dispersion coefficient on pressure of gas under condition of isotropy can be submitted as

![]() . (5.9)

. (5.9)

In areapod> LK (1) sprayed particles come back to the target both due to outdispersion, and due to outdiffusion, and dependence of the dispersion coefficient on pressure of gas looks like

(5.10)

(5.10)

As in magnetron sputtering systems working pressure is not strongly high, about0,3-1,5 Pa, the average length of path of ions and the sprayed atoms (λi, and λa) is higher, than distance between a cathode - target and a substrate d (λi, λa> d). Therefore there are no collisions between gas particles in the discharge. Thus, when calculating of the dispersion coefficient, influence of pressure can be neglected.

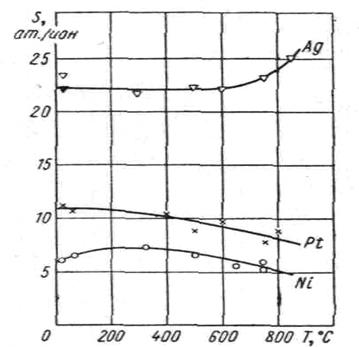

Influence of temperature of the cathode - target on quantity of atoms beaten out by one ion was studied by many authors. However even now it is impossible to approve definitely, whether the temperature is the parameter determining process of dispersion or not. There are many researches in which dependence the dispersion coefficient on temperature is not found out. At the same time in the some well operated experiences such influence was observed [32, 47, 87] (figure 5.15 and tab. 5.6).

Figure 5.15 Influence of the temperature on the dispersion coefficient of silver, platinum and nickel, irradiated by krypton ions with energy 45 eV and density of a current 10 … 100 mА/sm2.

Table 5.6 Dependence of the dispersion coefficients of various materials on energy of ions Cs + and temperatures.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.