The portability (mobility) of code Object Pascal allowing to simplify as much as possible carrying of the developed system software on other technical platform;

Flexibility and laconicalness of a code on Object Pascal.

Work of the software is conducted under the control of 32 digit operational systems of family Windows ® 95/98/ME/NT/2000, that allows to conduct multiline data processing, thus giving new opportunities on creation of the custom interface.

11.2.2 Tasks of software work

The executed work contains the decision of the following subtasks:

Research of object of automation (a substantiation of the opportunity of automation, necessity of performance of new development, choice of technical maintenance and tools).

The system analysis (realization of consecutive detailed elaboration of the system task with checking of a correctness of purpose of components for each level).

Development of algorithms of the problem decision (algorithms of realization of a set of the subtasks revealed during the analysis).

Development of architecture and synthesis of software (definition of character of interrelation of program units, a substantiation of the chosen structure of the interface and description of its elements and technologies of application).

Testing and debugging of system (the description of the examples confirming serviceability of the created software).

11.2.3 Development of interface

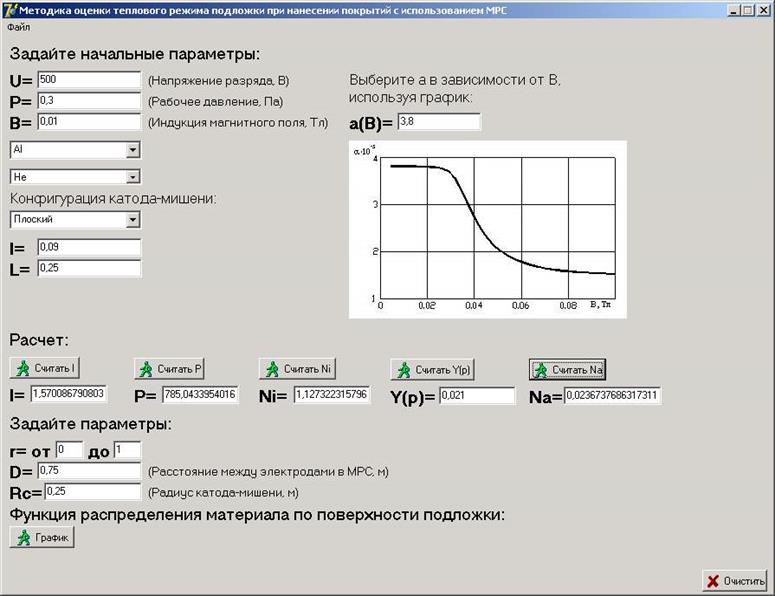

After program start the main window of the program (see figure 11.1) will appear. The window form of input of the initial data allows to input all parameters necessary for calculation. The user is offered to set values of a magnetic induction, working pressure, working voltage of MRS. The user can choose the configuration of cathode - target of MRS from available types (planar, cylindrical, disk-shaped).

There is also an opportunity to choose a kind of working gas and material of the cathode from the given database or to input other material. (see figure 11.1).

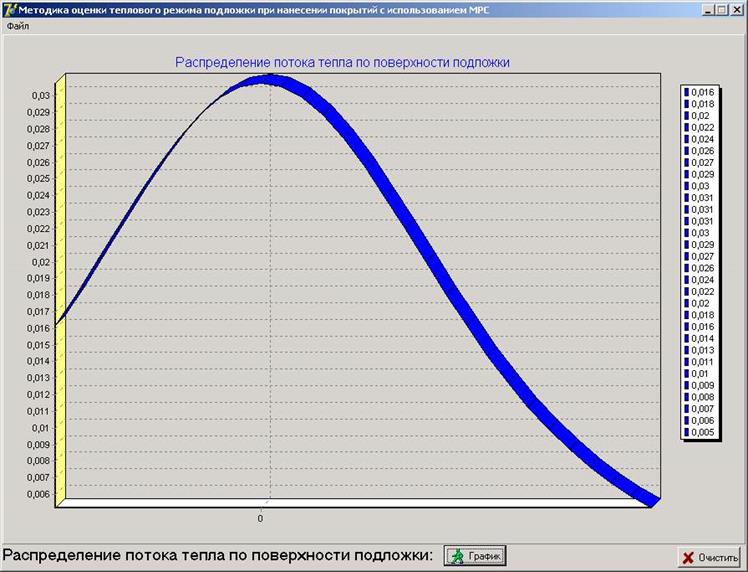

After the assigning of all parameters the software allows to carry out calculation of necessary parameters, and construct schedules of the material distribution and the heat flow distribution on a substrate surface.

Figure 11.2 Window form of the main window of a program complex.

Calculation of necessary parameters, such as discharge current, power put in the discharge, quantity of the ions bombarding a surface of a substrate, quantity sputtered atoms, quantity of the atoms sprayed from unit of the cathode - target surface in unit of time is made after assigning of the initial data and pressing button “ Count “. Results are represented in the numerical form.

Construction of schedules occurs after carrying out of all necessary calculations after pressing corresponding buttons.

Figure 11.2 Window form of heat flow distribution on a surface of a substrate.

Testing of developed software was made under the following functional characteristics:

а) Assigning of parameters, thus check on input of correct values is executed;

b) Check of the received

characteristics with values received in a different way is executed. Accuracy

of values is ![]() 5 % . This parameter is characteristic, that shows high

enough software work reliability;

5 % . This parameter is characteristic, that shows high

enough software work reliability;

c) Calculation results review;

d) Comparison of results of calculation with the received experimental data;

e) Saving of the results of calculation.

Mistakes were not revealed after carrying out the software testing by the designed earlier tests .

12. Comparison of the carried out estimations with experimental data

The purpose: carrying out of comparison of received data of the substrate heat mode estimation when drawing coverings with the help of magnetron sputtering systems with experimental data.

12.1 Methods of temperature measurement

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.