Thermal electric transducers find application in test chambers and at direct measurements of temperature. Thermal electric transducers are based on the phenomenonof thermoelectricity, opened in 1823 by Zeebek. This phenomenon consists that if one makes a circuit of two various conductors (or semiconductors)A andB, having connected them among themselves by the ends (See figure 12.1), than the temperature t1 of one splice is distinct from the temperature t2 of other splice, a current will flow in the circuit by action of electromotive force, named thermal electromotive force.

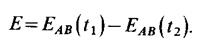

The further transformation of the metering circuit, disconnection of a contour (See figure 12.2), switching on conductors and millivoltmeter (figure 12.3) - allows to determine the value of thermal electromotive force:

(12.1)

(12.1)

Frequently several thermocouples are put in the electrotechnical product for measurement of temperature of its various parts. In this case the ends of thermocouples are connectted to the same device in turn. The design of the switch should provide the absence of contact between thermocouples at transition from one thermocouple to another, otherwise the hand will test sharp pushes. For equality of all thermocouples resistance, it is necessary to produce them with identical length of the ends and from one lot of wire. Besides, thermocouples should be verified among themselves after manufacturing.

Receivedtotal thermal electromotive force for the given pair of conductors depends only on value of absolute temperatures Т1, and Т2; and does not depend on length and diameter of thermoelectrodes, and also on their resistivity. Soldered joint of the thermocouple, placed in the medium with measurable temperature, is called running end (hot end), and end temperature of which is maintain constant, is called free end (cold end).

Thermocouples are connected to millivoltmeter or to potentiometer. The temperature of the hot end is determined by their indications.

The elementary fabrication method of the thermocouple (figure 12.4.a, b) consist in the following. Two wires 4 (for example, from alloys chromel and thaw) are braided at length 6 … 8 mm, after careful cleanup, and welded. It is possible to hammer the head 5 of thermocouple after welding by easy impacts of a hammer for paliform. Thermocouples with such heads are used for measurement of temperature of cores of machines and transformers. For thermocouple installation laminations are moved apart and a paliform head of the thermocouple is inserted into the formed crack .

At measurements it is necessary to remember, that a current passing through the thermocouple, depends on a difference of temperatures of a controllable point and the end of the thermocouple, connected to measuring device . Therefore for determination of temperature of a controllable point it is necessary to know the temperature in the measuring device location.

This property of the thermocouple allows to measure a difference of temperatures in two controllable points. To measure a difference of temperatures in two controllable points, two thermocouples are connected series-opposite.(figure 12.5).

Thermal electric transducers have a very wide range of measurement - from-200 up to 2200˚С (short-term up to 2500˚С). They can take temperature in the point of object or measured environment, have small overall dimensions - from 0,5 mm (big diameters of covers are defined by requirements of mechanical and thermal durability). Thermal electric transducers have enough high accuracy and stability of characteristics of transformation, though they yield a little on these parameters to thermal resistance converter.

It is necessary to relate to number of disadvantages necessity of special thermocouple wire application for connection of converters to the device and necessity of stabilization or automatic of free ends temperature.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.