Для создания наглядного эффекта движения кулачкового механизма, при создании профиля, мы можем передавать координаты профиля кулачка и параметры характеристик движения в системе T-FLEX CAD. В системе T-FLEX CAD, можно формировать рабочий чертёж и 3D твердотельную модель кулачка, совершать моделирование движения кулачковых механизмов в двумерных и трёхмерных координатах. T-FLEX CAD поддерживает OLE 2.0 (Object Linking and Embedding), путём функций системы OLE T-FLEX CAD, автоматизировано создаёт чертёж в формате GRB, затем формирует 3D модель кулачкового механизма. Поскольку база данных MS-Access популярная, а в T-FLEX CAD системе можно прямо получать информацию из MS-Access, мы передаём параметры характеристик движения кулачка базами данных MS-Access. Таким образом повышаем скорость моделирования и снижаем объём расчётов.

INTELLECTUAL DECISION SUPPORT SYSTEM FOR PRODUCTION SCHEDULING AND MANUFACTURING CONTROL

Lili Jiang

Dept of Mechanical & Electronic Eng., Guangdong University of Technology, Guangzhou, P.R.China

Key Words: CIM, Production Schedule, Shop-floor Control.

ABSTACT

The paper describes some recent results in application of special intellectual Decision Support System (DSS) for production scheduling and shop-floor control in Computer integrated manufacturing (CIM). The effectiveness of application of three scheduling policies based on Just-in-time Control is discussed.

The basic requirements to CIM lie in the necessity to timely fulfil the production plan with minimum costs and to ensure the desired quality. Therefore CIM control systems must be implemented and the control effort is required to overcome some typical Just-in-time difficulties. Nowadays all over the world special Short-term Planning Systems are being developed to improve the performance of the Enterprise Resource Planning (ERP) systems - manufacturing control systems based on MRP-II standard (such as SAP-R3, BAAN, Oracle Application). ERP-systems are the main control core of modern CIM enterprises, but most of them are based on invariable weekly or monthly plans and can meet unforeseen problems arising any working day.

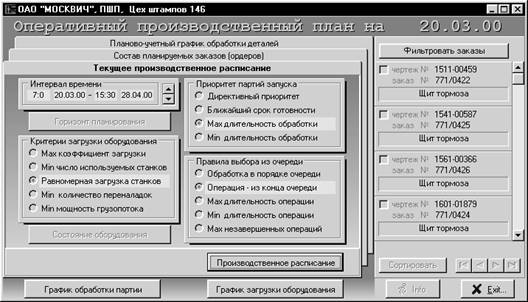

Fig.1. Scheduling criteria for Short-term Production Planning

So to provide Just-in-time control principles in manufacturing we have developed the software called FOBOS that encompasses special intellectual Decision Support System (DSS). Based on strong computational support (100 combinations of 14 criteria) FOBOS runs now at more then 30 big Russian industrial enterprises and 4 Chinese plants. Scheduling criteria are gathered in three groups (Figure 1):

Priority rules for Lots of workpieces:

Machines utilization policy:

Ordered Priority (ORD) Max. Mach. Utilization Index

Earliest Due Date (EDD) Min Numb. Of Mach. Involved

Longest Processing Time (LPT) Even Average Mach. Utilization

Shortest Processing Time (SPT) Min Number of Mach. Set-ups

Min Total Run of Vehicles

Sequence Priority in queues:

First in - First out (FIFO) Last in - First out (LIFO) Longest Operation Time (LOT) Shortest Operation Time (SOT).

FOBOS-DSS deals with a typical situation when the initial shop-floor schedule falls ineffective and its further implementation is undesirable because of an impending risk of Master production plan failure. Three different scheduling strategies are used (Figure 2):

§ Strategy 1: Rescheduling during the remaining interval from current time to the end of planning horizon ensuring minimal deviation from previous (already existing) schedule.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.