Mill power demand and operating conditions have to be within the 'tent" in order to avoid exceeding the design limit for motor current (4190 A) at mill speeds lower than 10.30 rpm, and to be within the available motor current at mill speeds higher than 10.30 rpm; e.g., available motor current at 10.30 rpm +5% is 4190A x 95% = 3980A. Any condition "outside the tent" would result in overheating of the motor; i.e., the DCS current value display would turn from "blue" to "red" as a warning. In Figure 7, a "red" condition would be expected between 9.3 rpm (73% C.S.) and 9.8 rpm (76% C.S.) in SAG 2 with 13% v/v balls and 28% v/v total, particularly if the mill is being slowed down under load. Should the ball volume increase to 15% v/v, motor torque rating would be increased by 6% to 4444 A as shown, which would "raise the tent peak" to 14242 kW (19,090 hp) motor rating. Such an increase in operating flexibility was designed into the cooling system for the thyristors in the "E" house at Alumbrera, thereby providing a modest contingency on the initial motor rating. This enabled the operators to maximize feed rates on harder ore by raising the ball charge volume to 15% v/v and operating at medium mill speeds (e.g., 9.5 rpm to 9.8 rpm) and 24% v/v to 25% v/v total mill charge volumetric loading for optimum power efficiency. The design of future SAG milling circuits for harder ores should exploit this operating philosophy. Incorporation of power draws at higher mill charge densities (e.g., 15% v/v balls and X 25% v/v total) into the mill design boosts confidence in scale-up for harder ores.

For many years, the "1,000 hp per ft of EGL" rule applied in assessing rated motor power for a 36 ft dia. SAG mill processing porphyry copper ore. The SAG mills at Alumbrera have demonstrated that this rule should be increased by 10%, especially for harder ores, and that by doing so, the mill and motor are capable of operating at a higher torque rating and power output at medium mill speeds and a higher ball charge volume (e.g., 15% v/v) for power efficiency, as well as giving the operators the capability to run the speed up when necessary with a higher total mill charge volumetric loading (e.g., 30% v/v).

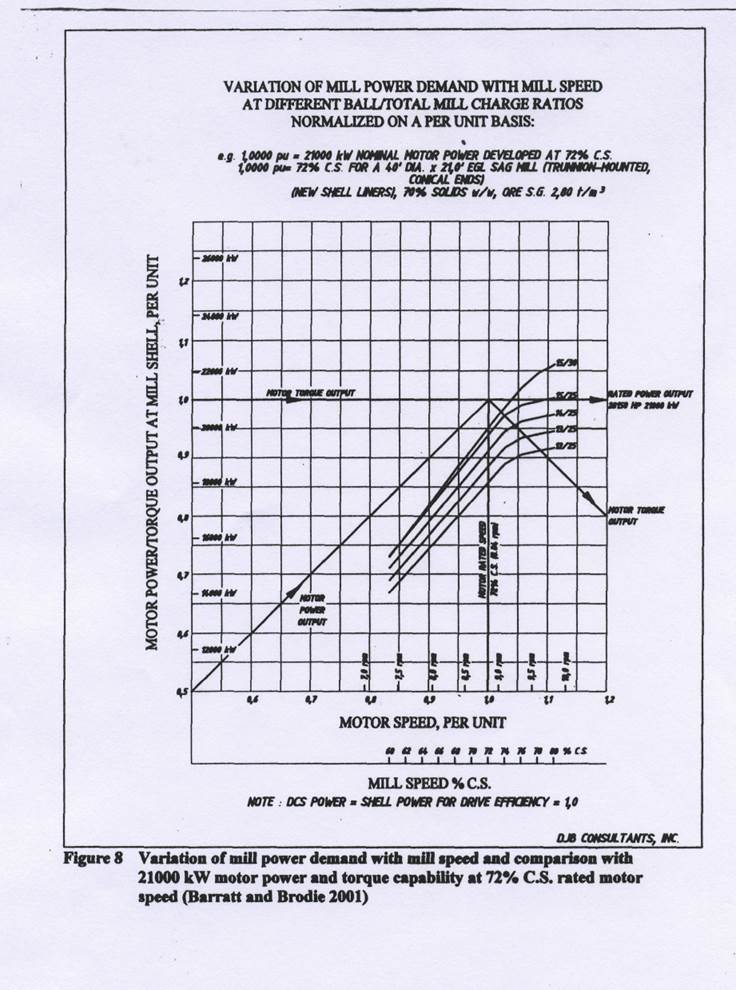

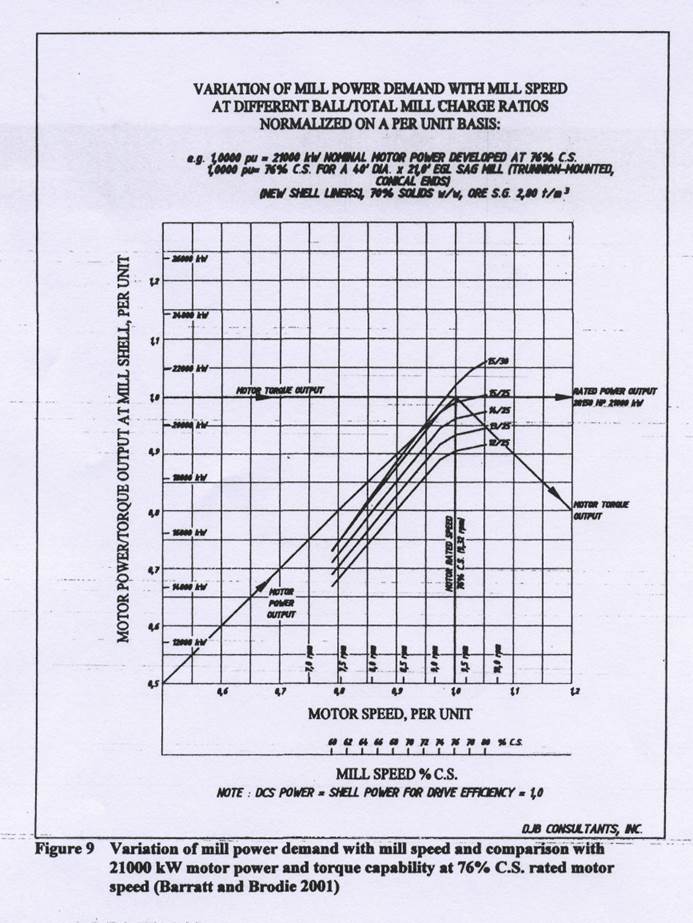

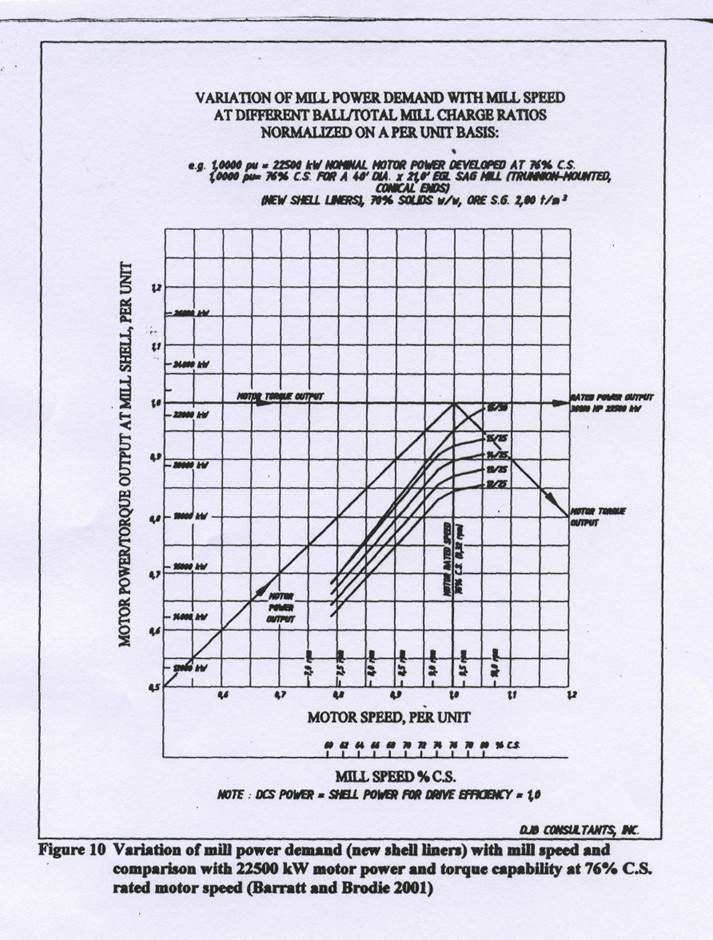

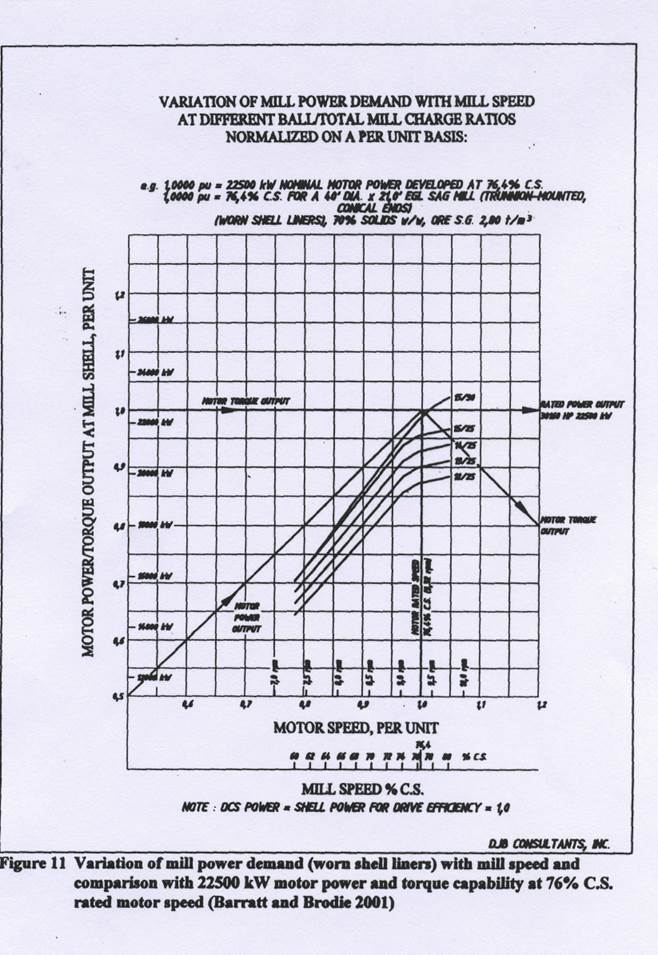

This operating philosophy leads into one of the most important factors in the selection of the motor for variable speed AG/SAG mills which is, in the authors' opinion, definition of the design or rated speed of the motor or, in other words, definition of the "peak" of the "tent"; i.e., the power output capability at that motor speed, or in the case of gearless drives, mill speed. This is very often an iterative process (Barratt and Brodie 2001), especially when bids from mill suppliers are being technically reviewed. Figure Nos. 8 and 9 illustrate the difference between selecting a lower mill speed at 72% C.S. and a higher mill speed at 76% C.S. for a 40 ft dia. x 21 ft EGL mill with a 21000 kW gearless drive and fitted with 52 or 39 rows of Hi-Hi lifters at 30° relief angle. Figure Nos. 10 and 11 take the issue to the next step of ensuring that the motor power output and torque output are sufficient to accommodate a 15% v/v ball charge at 30% v/v total mill charge volume with worn shell liners and raising the rated power to 22500 kW. This arrangement will allow the operators more flexibility in dealing with a range of softer to harder ores and also in optimizing shell liner/lifter design to assist in defining the range of "sweet points" for optimum power efficiency at higher null speeds. It is important to involve the mill vendor, liner supplier and liner handler supplier early in mill design process for optimization of liner design and liner replacement time.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.