Within the last five to six years, there has been a return toward Art MacPherson's dictum that the ratio of shell lifter height to spacing should be in the region of 4:1 in high aspect mills for optimum power efficiency, kWh/t (Meaders and MacPherson 1964, Bigg and Raabe 1996). Dynamic simulations developed by Rajamani (Rajamani toad Mishra 1996) have demonstrated that the design of AG/SAG mill shell liners/lifters should be based on mill operation at the highest planned mill speed to ensure that ball and rock trajectories concentrate at the toe of the charge for maximum impact and power efficiency at that speed, especially for harder ore types. This was proven at Alumbrera where a reduction, within six months of commissioning, in the number of rows of shell lifters from 72 to 48 of Hi-Hi and a change in relief angle from 7° to 30° improved power draw and throughput (Sherman 1999).

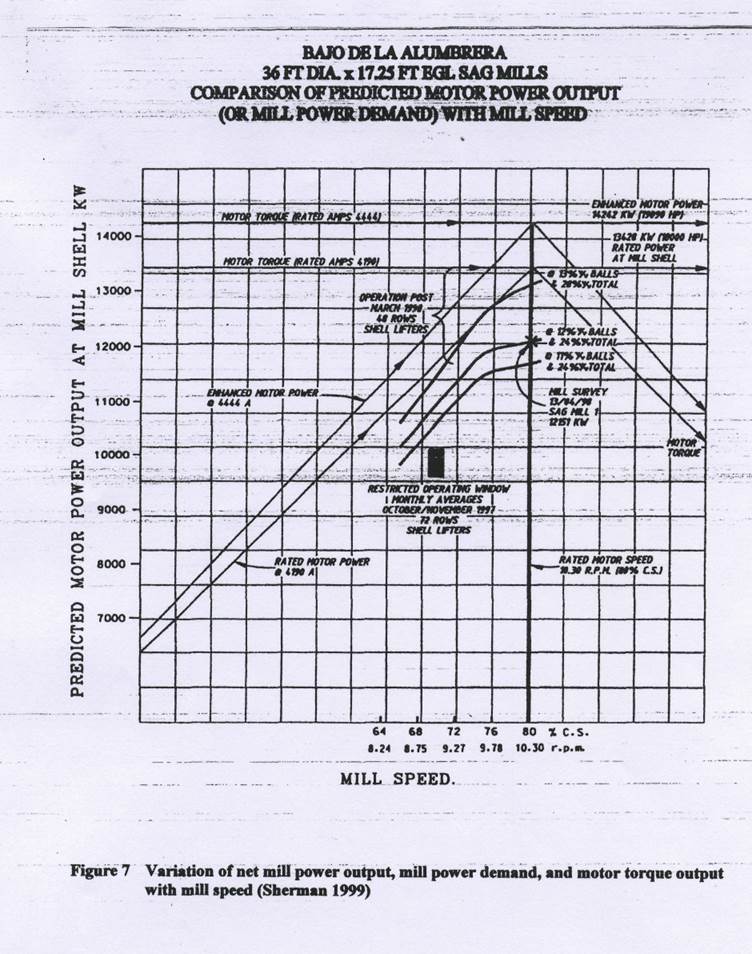

In Figure 7, the operating window for October and November, 1997 at Alumbrera is typical of the power draw and mill speed during the period with 72 rows of shell lifters from start-up in August/September, 1997 to March, 1998 for each of two 36 ft dia. x 17.25 ft EGL SAG mills, each powered by a 18,000 hp (13428 kW) gearless drive rated at 10.30 rpm for rated power. During this period, mill speed was restricted to the range 8.9 rpm and 9.1 rpm (69% C.S. to 71% C.S.) to limit the impact of errant ball trajectories and consequent premature damage to the shell liners and lifters. Packing between lifters resulted in late release of balls and errant ball trajectories striking at between 8 and 9 o'clock. Failure to key in the mill charge resulted in insufficient lift imparted to rocks and balls, particularly the larger rocks, and consequent power inefficiency (high kWh/t) and lower feed rates which averaged 1,500 t/h per line in the window.

Once the change to 48 rows of shell lifters was made in late March/early April, 1998, power draw increased, power efficiency improved (lower kWh/t), and throughput increased to the design rates of 1,852 t/h per line on average. A survey (see Figure 7) in SAG 1 on April 13 recorded 12151 kW vs 12087 kW predicted from the "CHARGEPOWER" section of "GRINDPOWER" for the measured charge volume of 12% v/v balls and 24% v/v total. In SAG 2 with a coarser feed, 13% v/v balls and 28% v/v total charge volume were measured and predicted power was being drawn over the full operating speed range up to 10.3 rpm. Note that in SAG 1, the rate at which power can be drawn diminishes above 75% C.S. at the lower total mill charge volume (24% v/v) with the finer feed. This trend is indicative of errant ball trajectories hitting the mill shell at the higher mill speeds and their failure to do useful work. In SAG 2 with 28% v/v total volume, mill power demand is increasing at a much faster rate; i.e., more power can be used for effective breakage of larger rocks on rocks and balls with a higher toe at higher mill speeds.

Comparison of these operating conditions, SAG 1 vs SAG 2, confirms the selection of 10.30 rpm (80% C.S.) as the rated speed of the motor/mill to effectively grind harder, more competent, and coarser mill feed, in combination with the improved shell liner/lifter design. With the softer and/or finer mill feed in SAG 1, the mill is slowed down and the operating conditions changed to stay within the capability of the motor, e.g., a slight reduction in the volumes of balls and ore with a small increase in the mill charge density: 3.924 t/m3 vs 3.816 t/m3 in SAG 2.

Figure 7 is also a "tent" diagram (Barrett and Brodie 2001) in which motor capability, as expressed by power and torque (current draw) outputs, is compared to the mill power demand required by the mill charge. The "tent" is described by the increase in motor power output at constant rated torque output (4190 A) as mill speed increases up to the rated design speed of the motor, 10.30 rpm (80% C.S.), and the rated motor power output of 13428 kW is reached, beyond which power output is constant and torque output (current) decreases.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.