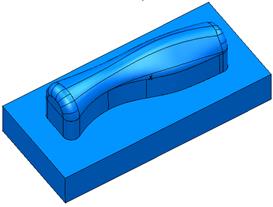

· Blank the cavity solid and switch on level 5.

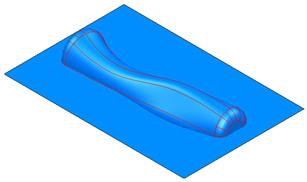

· Select the Z principal plane.

· Create a surface primitive plane at 0, width 80, length 120.

This surface does not need to be turned into a solid for the split command.

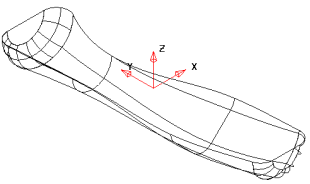

· Make the handle solid Active

· Select the plane and from the

Features menu, select solid split ![]()

· Delete the upper half of the handle

The solid has been split in half. If you shade the model you can see it more clearly.

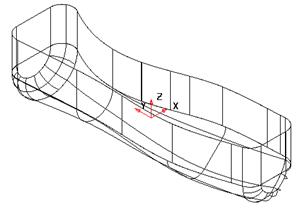

· Create a composite curve around the top edge of the handle.

· ![]() Open the Edits toolbar and

Project the curve to Z 0

Open the Edits toolbar and

Project the curve to Z 0 ![]()

· ![]() Make a solid extrusion 15mm up Z.

Make a solid extrusion 15mm up Z.

· Add the extrusion to the handle.

By projecting the curve onto Z0, it adjusts any tolerance errors when tracing the composite curve.

The extrusion can then be added

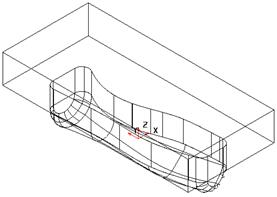

· Create a solid block at 0 0 15, length 60, width 130, height 20.

· ![]() Add the two solids together.

Add the two solids together.

· Rename the solid as Cavity_Electrode.

· Put the new solid, on level 5 and switch the level off.

A new insert can now be made.

· Select Unblank and Activate the Cavity solid.

· Select Principal Plane along Y.

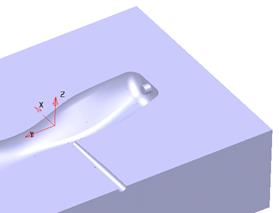

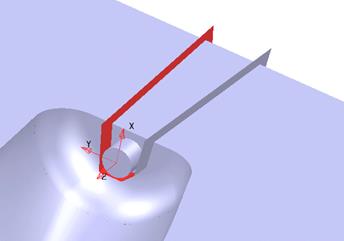

· Create a Solid Cylinder at 4.0 –52.0 -3.0 Radius 2.0 length 5.0

· Select the solid cylinder and Add

it to the active solid. ![]()

The solid now has an internal protrusion. A workplane is going to be created at the end of this protrusion to assist with the creation.

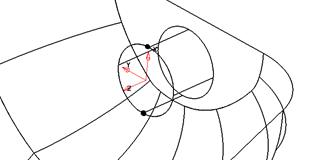

· ![]() Create a WorkPlane

between these 2 points

Create a WorkPlane

between these 2 points

Hint, create a line between the two points and then you can snap to the mid-point.

· ![]()

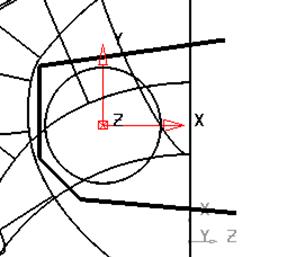

![]() Select Principal Plane along Z and Lock the

plane

Select Principal Plane along Z and Lock the

plane

![]()

· Select a view down the Z axis

·  Sketch the shape of the loose piece or slide around the cylinder

as shown.

Sketch the shape of the loose piece or slide around the cylinder

as shown.

· Make a composite curve from the lines.

![]()

· ![]()

![]() Unlock the plane

Unlock the plane

![]()

· Select the wireframe and create a Solid Extrusion.

· Double click over the solid extrusion

· Enter a Negative length of 30, Draft angle 2 and Length 0

· Select Accept

The extrusion is the right size and shape.

· Make sure the main Die insert solid is the active solid.

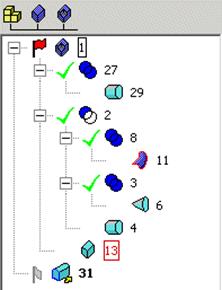

· In the Feature Tree area expand all the +symbols so the full history of the active solid can be seen working from the bottom upwards

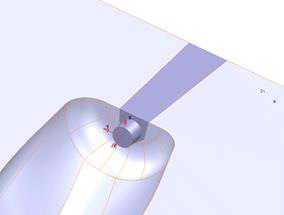

· Select the solid extrusion

and Split active with selected solid. ![]()

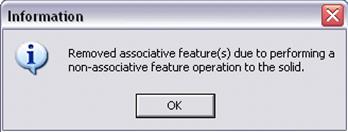

This is a warning to let you know that any associative features will be removed (the history will be lost).

· Click OK

Most solid operations are associative so the Solid history can be kept and updated but this particular operation divides the solid into 2 separate entities as shown.

The History has been lost for the Die insert so it might be useful to undo this operation and create a copy of the original solid for reference/modification purposes.

· Open a new model

· Create a workplane at 0 and rename it Datum.

·  Generate a rectangle from -125

–150 with a size of X 250, Y 300.

Generate a rectangle from -125

–150 with a size of X 250, Y 300.

· Change the rectangle into a composite curve.

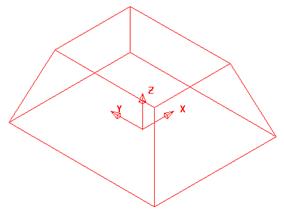

· Generate a solid extrusion up the Z-axis using the Solid extrusion icon.

· Change the extrusion length to 130 and Draft Angle to 340 and Accept.

This has formed the basic shape of the Alarm Box.

The features can now be added.

· Generate a rectangle from -60 –80 130 with a size of X 120, Y 160.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.