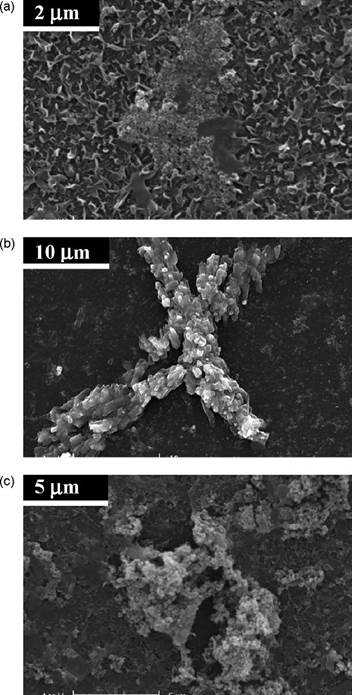

Fig. 7. Scanning electron micrographs of (a) lead, (b) middle, and (c) tail polyamide membranes from the secondary RO after operating approximately 1000h at 68% secondary RO water recovery (95% overall water recovery).

ensuring sufficient Ca2+ and SiO2 removal in the SCR via a robust and effective feedback control strategy would be required to avoid excessive and detrimental membrane fouling and scaling by these compounds in long-term implementation of the PRO–ICD–SRO process.

A 9-month pilot scale demonstration of high water recovery brackish water desalting of Colorado River (CR) water was conducted by integrating a primary RO (PRO) desalting with interstage chemical demineralization (ICD) followed by secondary RO (SRO) desalting. Initial Phase I pilot testing demonstrated that ICD via alkaline-induced (NaOH) precipitation of primarily CaCO3 (in addition to the ensuing co-precipitationofothermembranescaleprecursors)intheSCR led to significant removals of various membrane scale precursors. At SCR effluent pH of above 10, Ca2+, Ba2+, Sr2+, Mg2+, and SiO2 removals from the PRO concentrate were in the ranges of 94–97%, 97–98%, 88–95%, 38–80% and 67–85%, respectively. In addition, 11–42% DOC removal was observed over the range of pH levels tested (pH 9.2–11.3). Phase I pilot testing alsorevealedtheimportanceoftheSCRpHasakeydetermining indicator of SCR operating efficiency.

In subsequent Phase II pilot testing, the implementation of the PRO–ICD–SRO process to achieve up to 95% overall water recoverywasdemonstratedandevaluatedovera4-monthperiod. While maintaining an SCR effluent pH above 9 was sufficient to produce SRO concentrate with CaSO4, SrSO4, and BaSO4 saturationlevelswithinsafelevelstominimizemembranescaling(at orbelowthoseinthePROconcentrate),thermodynamicanalysis indicated the need for operating the SCR to achieve higher effluent pH (10.5–11.5) in order to reduce the saturation level with respect to SiO2 to avoid silica scaling. Significant variations in SCR effluent pH suggested that the impact of process variations, particularly in the PRO concentrate water quality, must be considered during the process design stage. Specifically, a robust control and operation strategy of the SCR must be developed andimplementedtomaintainconsistentlyhighdemineralization efficiency (e.g., by maintaining consistent SCR effluent pH).

Despite process variations which were encountered during the pilot study of the PRO–ICD–SRO process, SRO desalting stage operations at 91% and 95% overall water recovery were demonstrated with normalized salt passage of 2.3±0.4% and 2.9±0.7%, respectively, and with less than 10% variations (two times the standard deviation) in the specific permeate fluxes over a total run-time of ∼2 months without requiring membrane cleaning. Membrane fouling and scaling by silicates and CaSO4, as revealed through membrane autopsies, delineated the importance of both selection and use of appropriate make-up antiscalant for the SRO stage and maintaining consistent SCR demineralization efficiency, primarily with respect to calcium and silica removal.

This project was sponsored by the Desalination Research and

Innovation Partnership with funding provided by the California EnergyCommission(contract#400-00-013),U.S.Environmental Protection Agency (contract # XP-98973001-0), California Department of Water Resources, UC Water Resources Center, andanInternationalDesalinationAssociationScholarshiptoMr. AndityaRahardianto.TheauthorswishtoacknowledgeMichael Norris and Angela Adams with the U.S. Bureau of Reclamation, andBrentCorbettofBurnsandRoeServiceCorporationfortheir support and efforts in conducting the pilot-scale investigations at the Water Quality Improvement Center in Yuma, AZ.

[1] J.S.Taylor,E.P.Jacobs,Reverseosmosisandnanofiltration,in:WaterTreatment: Membrane Processes, AWWA, Lyonnaise des eaux, Water Research Commission of South Africa, McGraw-Hill, New York, NY, 1996, p. 9.1.

[2] A. Almulla, M. Eid, P. Cote, J. Coburn, Developments in high recovery brackish water desalination plants as part of the solution to water quantity problems, Desalination 153 (2003) 237.

[3] I. Bremere, M. Kennedy, P. Michel, R. van Emmerik, G.J. Witkamp, J. Schippers, Controlling scaling in membrane filtration systems using a desupersaturation unit, Desalination 124 (1999) 51.

[4] I. Bremere, M.D. Kennedy, A. Johnson, R. van Emmerik, G.J. Witkamp, J.C. Schippers, Increasing conversion in membrane filtration systems using a desupersaturation unit to prevent scaling, Desalination 119 (1998) 199.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.