Thin-Film

Processes Yield Resistors, Filters for Broadband Uses

Thin-Film

Processes Yield Resistors, Filters for Broadband Uses

|

W |

orldwide, wireless broadband services are making steady progress. Last year, Japanese service providers were the first to begin offering wide-band code division multiple access (W-CDMA) services. To accelerate the transfer speeds for wireless broadband systems of the future will require use of frequencies in the microwave and millimeter-wave bands. Studies today focus on the adoption of wireless local area networks (LANs) using 2.4GHz, 5GHz and 60GHz bands. Researchers also are looking at broadband wireless access systems using 26GHz and 38GHz bands.

Communications using optical transmission have accelerated from 2.5Gbps to 10Gbps, and even, in some cases, 40Gbps, using trunk transmission. Continuous acceleration of performance characterizes the components in these systems. Speed also is characteristic of non-voice communications systems. Many of Japan’s highways last year adopted an electronic toll collection system that works in the 5GHz band. Meanwhile, researchers are studying the Dedicated Short-Range Communications (DSRC) system, a 5.8GHz wireless communications system in Japan. As communications frequencies have risen, Murata Manufacturing Co., Ltd. has continued to develop various multiplechip module (MCM) filters. These are the key devices in communications modules and duplexers. As part of this development, the company has applied its thinfilm fine-fabrication technology to ceramic boards.

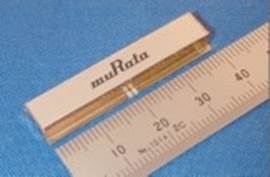

MCM band-pass filter and low-pass filter

Thin-Film Circuit Substrate

Gold electrodes provide outstanding highfrequency characteristics and superior bonding properties. Murata Manufacturing’s thinfilm, fine-fabrication technology works at a minimum pattern width of 30µm, or 20µm for aluminum. The technology also permits the formation of thin-film resistors on the same pattern surface. Therefore, it is easy to form an inductance-resistance-capacitance (LCR) circuit on the substrate. Engineers use tantalum nitride for the resistors,

|

Relative permittivity (eg) |

Q ( = 1/tan d ) |

Temperature coefficient (-25˚C to 85˚C) |

L/S (µm) |

Uses |

|

|

1 |

9 |

3500 (at 6 GHz) |

---- |

20/20 |

High power |

|

2 |

10 |

3600 (at 12 GHz) |

100 (ppm/ ˚C) |

20/20 |

High-frequency circuits |

|

3 |

39 |

6000 (at 7 GHz) |

0 (ppm/ ˚C) |

30/20 |

High-frequency circuits |

|

4 |

90 |

>10000 (at 1 MHz) |

-330 (ppm/ ˚C) |

30/20 |

High-frequency circuits |

|

5 |

150 |

>100000 (at 1 MHz) |

-750 (ppm/ ˚C) |

30/20 |

High-frequency circuits |

|

6 |

250 (under development) |

>5000 (at 1 MHz) |

-1000 (ppm/ ˚C) |

30/20 |

High-frequency circuits |

|

7 |

300 |

>4000 (at 1 MHz) |

-2200 (ppm/ ˚C) |

30/20 |

High-frequency circuits |

|

8 |

3000 |

Tan δ = 0.9% (1kHz) |

±10 (%) |

30/20 |

Strong dielectric constant |

Table 1: Materials for thin-film substrates

26GHz-band fixed wireless access duplexer

because this material offers superior stability. It exhibits resistance values of 25Ωh and 50Ωh when serving in sheet resistors.

Dielectric Filters

Using these dielectric material technologies and thin-film fine-fabrication technologies, Murata Manufacturing is developing communications components for microwave and millimeter-wave bands. The company offers 26GHz MCM filters (Fig. 1) that will fit in the same package with monolithic microwave ICs (MMICs). Compound packaging and a proprietary circuit design technology enable the insertion of an attenuation pole at low bands, unlike conventional microstrip line filters, even though the products use the transverse electric and magnetic (TEM) mode. Attenuation thus reaches 15dB or more at 50MHz below the center frequency.

Planar filters using the transverse electric (TE) mode attain compact designs and offer excellent productivity. They also are easy to mount, compared with conventional filters that use waveguides. These features are the result of the TE-mode resonator design technology and thin-film circuit technology. Use of this filter technology enabled Murata Manufacturing to

![]()

Copyright © 2002 Dempa Publications, Inc.

IF

IF

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.