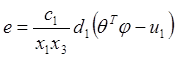

. (19)

. (19)

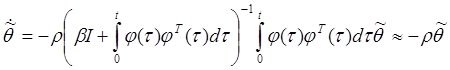

Analysis of the error model (19) motivates the following structure of adaptive controller

![]() (20)

(20)

where the vector

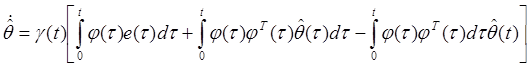

of adjustable parameters ![]() is generated by the

adaptation algorithm with improved parametric convergence [6].

is generated by the

adaptation algorithm with improved parametric convergence [6].

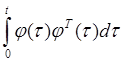

(21)

(21)

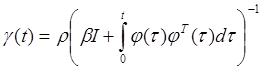

with gain function

,

, ![]()

where ![]() is a small constant.

is a small constant.

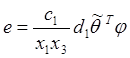

Taking

(20) in (19) and transforming equation (21) we obtain the parametric error ![]() and stabilization error

and stabilization error ![]() models of the closed loop

system:

models of the closed loop

system:

, (22)

, (22)

. (23)

. (23)

Thus adaptive control law proposed is described by equations (21):

(13), (14) – state observer;

(20) – adjustable controller;

(21) – adaptation algorithm.

Properties of the closed loop system are established by the following

proposition: for any ![]() and

any initial conditions all the signals in the closed loop system consisting of

the plant (7), (9), state observer (13), (14) adjustable controller (20) and

adaptation algorithm (21) are bounded and additionally

and

any initial conditions all the signals in the closed loop system consisting of

the plant (7), (9), state observer (13), (14) adjustable controller (20) and

adaptation algorithm (21) are bounded and additionally ![]() as

as ![]() asymptotically if

elements of matrix

asymptotically if

elements of matrix  are

linearly independent. Moreover the rate of parameter convergence and the

speed of the closed-loop system can be arbitrary increased with increasing

parameter

are

linearly independent. Moreover the rate of parameter convergence and the

speed of the closed-loop system can be arbitrary increased with increasing

parameter ![]() that results from equation (23).

that results from equation (23).

Remark 2: In spite of perfect

convergence some integrals in the expression (21) grow unboundly as ![]() . Therefore in practice

resetting of integration in definite time period has to be used

. Therefore in practice

resetting of integration in definite time period has to be used

3. Nonlinear torque control

At the stage of torque control synthesis we assume that engine

parameters ![]() ,

, ![]() ,

, ![]() are determined in the course of experiment

and a priory known.

are determined in the course of experiment

and a priory known.

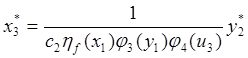

To provide asymptotic convergence of indicated torque according to

expression (12) let us define the reference signal ![]() using

equation (10) as

using

equation (10) as

![]() (24)

(24)

where ![]() is the reference signal of air pressure in

the intake manifold. Let us express

is the reference signal of air pressure in

the intake manifold. Let us express ![]() as

as

. (25)

. (25)

Now we introduce

error signal ![]() where

where ![]() is

the state variable of reference model

is

the state variable of reference model

![]() ,

, ![]() . (26)

. (26)

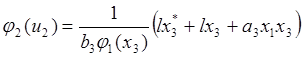

Let us define the error model as

![]() (27)

(27)

that provides asymptotic tracking of signal

![]() . Assuming that the

subsystem described by equation (6) is stable (i.e. engine works at stable

regimes) and analyzing error model (27) we obtain the following control law:

. Assuming that the

subsystem described by equation (6) is stable (i.e. engine works at stable

regimes) and analyzing error model (27) we obtain the following control law:

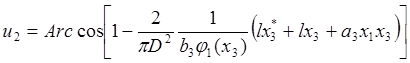

(28)

(28)

or

. (29)

. (29)

Thus the torque regulator is presented by equations (25) and (29).

For any ![]() and any initial conditions all

the signals in the closed loop system consisting of the stable plant (6), (8),

(10) and regulator (25), (29)

and any initial conditions all

the signals in the closed loop system consisting of the stable plant (6), (8),

(10) and regulator (25), (29) ![]() as

as ![]() asymptotically.

asymptotically.

4. Simulation

To confirm validity of engine model and illustrate the work of closed loop system MathLab/ Simulink software is used. Engine parameters and approximations of static functions of the engine (Ford 840 Ci, motronic) model are presented in tables 1 and 2 [10]. Parameters of air to fuel ratio controller (13), (14), (20), (21) and torque controller (25), (29) are presented in table 3.

Table 1. Engine parameters. Table 2. Static functions.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.