|

№ |

Manual soldering |

Duration, min |

|

1. |

To extract plate from container |

0,1 |

|

2. |

To establish plate on a support |

0,3 |

|

3. |

To take a brush |

0,08 |

|

4. |

To type the flux on a brush |

0,08 |

|

5. |

To flux places of soldering |

0,38 |

|

6. |

To postpone a brush |

0,08 |

|

7. |

To take an electrosoldering iron |

0,09 |

|

8. |

To type solder on a soldering iron |

29,7 |

|

9. |

To solder conclusions of an electronic component |

33 |

|

10. |

To postpone a soldering iron |

0,09 |

|

11. |

To check up quality of soldering |

0,25 |

|

12. |

To remove plate from a support |

0,27 |

|

13. |

To lay plate in container |

0,21 |

|

№ |

Automated soldering |

Duration, min. |

|

1. |

To extract plate from container |

0,1 |

|

2. |

To extract paper masks under the form and the sizes appropriate to segments of plate, protected from solder |

0,32 |

|

3. |

To take a brush |

0,08 |

|

4. |

To type the flux on a brush |

0,08 |

|

5. |

To put a flux on the protected places of soldering and on masks |

0,82 |

|

6. |

To postpone a brush |

0,08 |

|

7. |

To paste masks on the protected places |

0,15 |

|

8. |

To lay plate in heating cartridges |

0,27 |

|

9. |

To include a line of soldering |

0,05 |

|

10. |

To solder plate on the plant |

0,49 |

|

11. |

To remove the cartridge from the plant |

0,11 |

|

12. |

To remove plate from the cartridge |

0,12 |

|

13. |

To remove a mask from plate |

0,52 |

|

14. |

To check up quality of soldered connections |

0,25 |

|

15. |

To take an electrosoldering iron |

0,09 |

|

16. |

To type solder on a soldering iron |

2,97 |

|

17. |

Solder defective connections |

3,3 |

|

18. |

To postpone a soldering iron |

0,09 |

|

19. |

To lay plate in container |

0,21 |

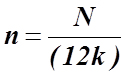

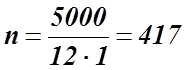

Calculation of the party size:

, where

, where

![]() - quantity of parties during one month, we take

- quantity of parties during one month, we take ![]()

it.

it.

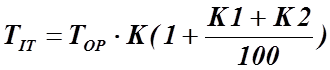

-

item time, where

-

item time, where

![]() - a correction coefficient

with which help take into account group of complexity and type of manufacture,

- a correction coefficient

with which help take into account group of complexity and type of manufacture, ![]() ;

; ![]() - Interest from the

operative time, appropriate to preparing-final time, time for service of a

workplace etc.,

- Interest from the

operative time, appropriate to preparing-final time, time for service of a

workplace etc., ![]()

![]() - interest from the

operative time, appropriate to time for rest,

- interest from the

operative time, appropriate to time for rest, ![]()

![]() -

operative time (from the table)

-

operative time (from the table)

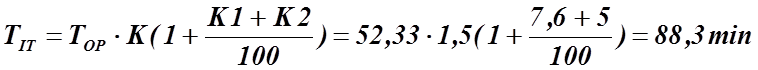

Calculation of piece time for manual soldering

![]()

Calculation of piece time for the automated soldering

![]()

Calculation of item-calculation time for manual soldering

![]() , where

, where

![]() - a volume of the party

processable from one adjustment;

- a volume of the party

processable from one adjustment;

![]() - preparing-final time

- preparing-final time

![]() for manual soldering. We

determine

for manual soldering. We

determine ![]() For

For ![]() and

and ![]()

![]()

![]()

![]()

![]()

![]()

![]()

Calculation of ITEM-calculation time for the automated soldering

![]() , where

, where

![]() for a line of soldering

АP-4. We determine

for a line of soldering

АP-4. We determine ![]() for

for ![]() and

and ![]()

![]()

![]()

![]()

![]()

![]()

![]()

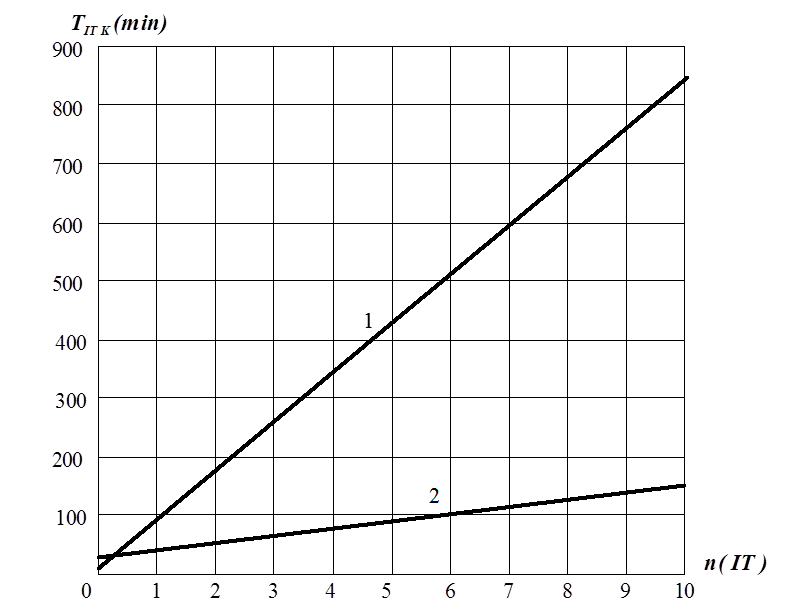

Figure 1. Optimization of soldering

Schedules ![]() Are shown on figure 1.

From schedules it is possible to draw a conclusion, that manual soldering (1)

is optimum at soldering less than one plate in change. At soldering one and

more plates in change the automated soldering (2) wave of solder is optimum.

Are shown on figure 1.

From schedules it is possible to draw a conclusion, that manual soldering (1)

is optimum at soldering less than one plate in change. At soldering one and

more plates in change the automated soldering (2) wave of solder is optimum.

Calculations of the cost price and the price of manufacturing of printed-circuit-boards

The consumer markets of the given product may be electro radio factories and the enterprises that are engaged in assembly of printed-circuit-boards.

Competitiveness of the given product is provided due to availability and simplicity of element base, efficiency in technological process.

For radio-electric devices it is the most convenient to calculate expenses for logistics products. For this purpose it is enough to have the principal diagram of the device and the specification to it. Calculation of quantity and the cost of logistics products are listed in table, appendix 2. The prices for logistics products it is received equal market.

The structure of the full cost price of printed-circuit-boards is listed in table

The table

|

The article of expenses |

Share of the cost price, % |

Share of the cost price, UAH |

|

The main materials |

10 |

34,35 |

|

Logistics products |

48 |

53,1 |

|

The salary of industrial workers |

16 |

54,96 |

|

Consumptions on operation of the equipment |

24 |

82,44 |

|

Общезаводские расходы |

12 |

41,22 |

|

Unindustrialized consumptions |

3 |

10,31 |

|

Total the full cost price |

100 |

276,38 |

The main materials are printed-circuit-board on which in a consequence radioelements will be located.

Consumptions on operation of the equipment - the consumptions called by repair and service of the equipment.

Manufacturing consumptions are the consumptions called by transportation of products and materials between shops.

Unindustrialized consumptions - called by warranty service and replacement of defective elements.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.