![]() Our apparatus is based on a large capacitor with two

80-cm-diam aluminum plates, held apart with a 10-cm spacing. The lower plate is

grounded, and the upper plate, has a banana plug in the top so that, the

connection to it may easily be opened and closed. The capacitor is driven from

a small powdered iron torus transformer (Ferroxcube 400 T 750) which is wound

with a ratio of 50 primary to 1000 secondary turns. This matches the capacitor

to a 600 Q audio oscillator

Our apparatus is based on a large capacitor with two

80-cm-diam aluminum plates, held apart with a 10-cm spacing. The lower plate is

grounded, and the upper plate, has a banana plug in the top so that, the

connection to it may easily be opened and closed. The capacitor is driven from

a small powdered iron torus transformer (Ferroxcube 400 T 750) which is wound

with a ratio of 50 primary to 1000 secondary turns. This matches the capacitor

to a 600 Q audio oscillator

Nolcs and Discussions

(Hewlett Packard, Model 200CD or equivalent,) , so that there is a voltage of one hundred volts

![]()

across the capacitor at about '20 kHz.![]()

![]() The magnetic induction pickup coil is in thc form of a

torus and is made as follows: A 238-cmlong, 1.27-cm-radius rubber vacuum hose

is wound

The magnetic induction pickup coil is in thc form of a

torus and is made as follows: A 238-cmlong, 1.27-cm-radius rubber vacuum hose

is wound ![]() with

14 000 turns of No. 38-gauge Formvar insu-

with

14 000 turns of No. 38-gauge Formvar insu- ![]() lated

wire. This can be donc by threading a dowel through the tubing and using a hand

drill as a

lated

wire. This can be donc by threading a dowel through the tubing and using a hand

drill as a ![]() rotating

device. The wire is glued onto the tube with silicone RTV cement just to

fogilitate han

rotating

device. The wire is glued onto the tube with silicone RTV cement just to

fogilitate han![]()

![]() dling.

The wire is insulated and protected against

dling.

The wire is insulated and protected against

![]()

abrasion by a larger thin rubber hose, (1.27-cm inside, radius, 4-mm thick wall) which is slit lengthwise, slipped over the coil and taped securely with mylar tape.

![]() Copper

shielding foil is added as shown in Fig.

Copper

shielding foil is added as shown in Fig. ![]() 2(b)

; the tubing is bent into a circle, excess end

2(b)

; the tubing is bent into a circle, excess end ![]()

![]()

rubber is cut off, and the tubing plus shielding is ![]()

![]()

![]() attached

to a piece of plywood backing in order

attached

to a piece of plywood backing in order ![]() to

hold it rigidly. The plywood piece hos a large

to

hold it rigidly. The plywood piece hos a large![]()

![]()

hole cut in the middle. and has a handle as shown![]()

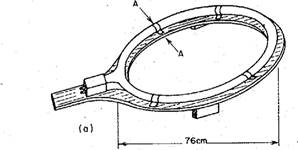

![]() in Fig. 2(a). At the junction of the handle. and

in Fig. 2(a). At the junction of the handle. and ![]() the

torus, the two ends of the toroidal coil are brought to a 1:1 audio-output

transformer with

the

torus, the two ends of the toroidal coil are brought to a 1:1 audio-output

transformer with![]()

![]()

secondary center tapped.

(b)

![]()

![]()

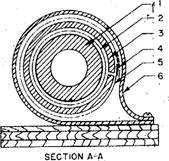

![]() FIG. 2. (a)

Toroidal coil assembled on plywood or phenolic bourd brace. (b) Cross section

A—A of toroidal coil showing: (l) rubber tubing form; (2) wire windings; (3)

outer insulating tubing; (4) Mylar tope to insulate overlapping portion of (5)

cepper shielding foil • about 0.0025 cm thick; (6) plastic hose or coble clamp.

FIG. 2. (a)

Toroidal coil assembled on plywood or phenolic bourd brace. (b) Cross section

A—A of toroidal coil showing: (l) rubber tubing form; (2) wire windings; (3)

outer insulating tubing; (4) Mylar tope to insulate overlapping portion of (5)

cepper shielding foil • about 0.0025 cm thick; (6) plastic hose or coble clamp.

AJP Volume 42

/ 247![]()

Notes and Discussions

Probably any audio interstage transistor

transformer will do here, but ours was made from a powdered iron Ferroxcube

528T 500 toroidal form wound with 400 turn primary and 400 turn center-tapped

secondary. In order to be, conservative about stray pickup, the secondary was

wound with 20() turns right-handed, and 200 turns overwound left-handed, and

the starting points of these two coils were used as the common secondary center

tap which was connected to the shielding foil. The secondary of this

transformer is led by two shielded RG/59U or equivalent cables to the

differential input amplifier terminals of a ![]() laboratory

type oscilloscope.

laboratory

type oscilloscope.

![]() It is important to notice that this type of connection,

from the coil to the oscilloscope, is essential to the elimination of unwanted

stray

It is important to notice that this type of connection,

from the coil to the oscilloscope, is essential to the elimination of unwanted

stray ![]() pickup

Voltages. The desired signal is push-pull or differential in na.ture. The small

1 :1 trans

pickup

Voltages. The desired signal is push-pull or differential in na.ture. The small

1 :1 trans![]() former

helps to reject the common-mode pickup voltage. Common-mode, rejection is

improved by

former

helps to reject the common-mode pickup voltage. Common-mode, rejection is

improved by ![]() using

an oscilloscope (in our case a Tektronics

using

an oscilloscope (in our case a Tektronics ![]() 503)

with a good differential amplifier input with sensitivity of about 1 mV/cm. Thc

shielding of the coil is important, and it also helps greatly to incltlde the

small transformer mentioned within the copper foil shielding. The center tap of

the transformer secondary is grounded to the shielding.

503)

with a good differential amplifier input with sensitivity of about 1 mV/cm. Thc

shielding of the coil is important, and it also helps greatly to incltlde the

small transformer mentioned within the copper foil shielding. The center tap of

the transformer secondary is grounded to the shielding.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.