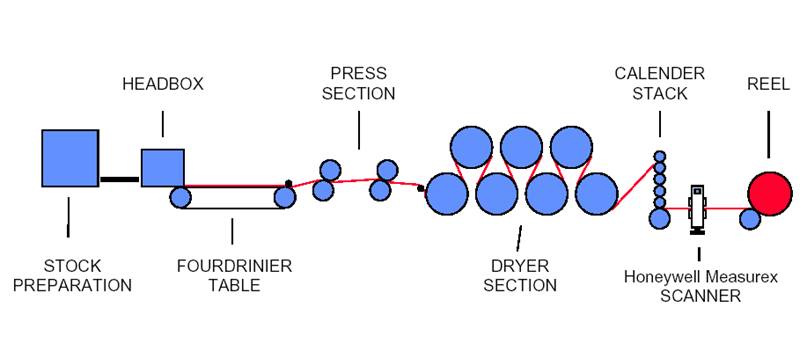

Speed measurements are used for machine set-up and production information. Typically they are taken at the fourdrinier table (wire speed) and at the dryer section or reel (machine speed).

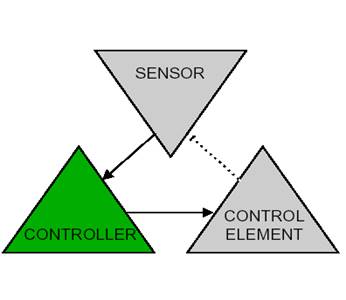

The objective of the controller is

to:

• process the input signal from the

sensor

• compare the desired process

value to the input signal from the

sensor

• act to reduce the error and bring

the actual value toward the

desired value

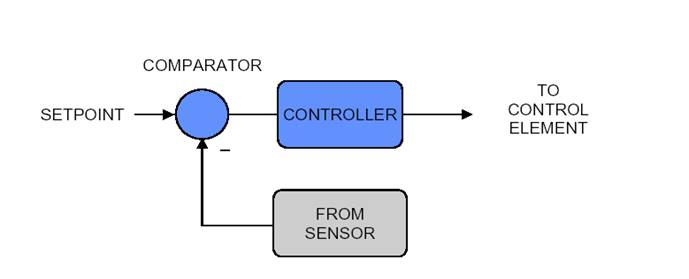

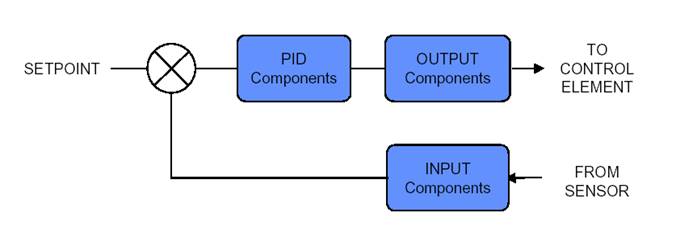

All feedback control systems have a comparator and a controller.

The comparator takes the difference between the setpoint and the sensor signal. The error signal, which is the output of the comparator, becomes the input to the feedback controller. Based on the error signal from the comparator, the controller calculates a signal to the final element. The mathematical function performed in the controller is determined by the process dynamics.

Today’s modern controllers use proportional, integral, and derivative (PID) functions.

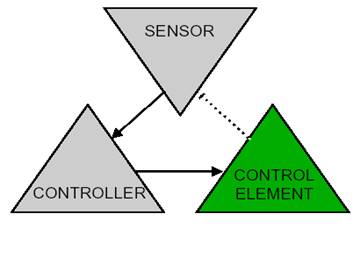

The output of the controller is

a signal to the final control

element which governs the

control of the manipulated

variable.

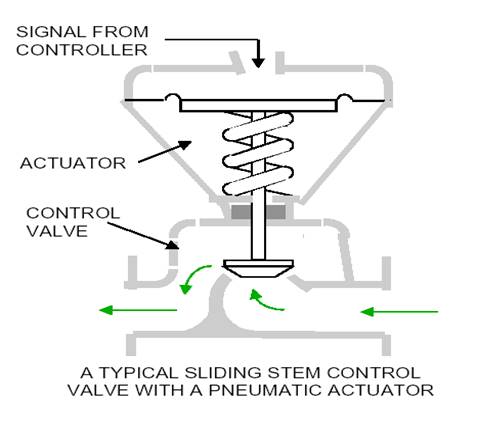

In many process control systems, the final control

element is a valve - which is typically driven by an actuator. The actuator moves the stem of the control valve to open or close the valve. Control valve actuators may be pneumatic,

electric, hydraulic, or manual.

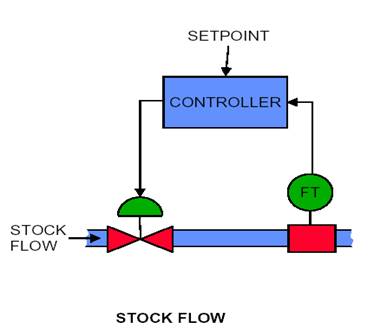

The amount of stock placed on the wire determines the basis weight of the finished sheet. For example; if

the sheet was too light, the operator would increase the

setpoint of the stock flow controller. This action would

cause the stock flow valve to open, placing more stock on the wire and increasing the sheet weight.

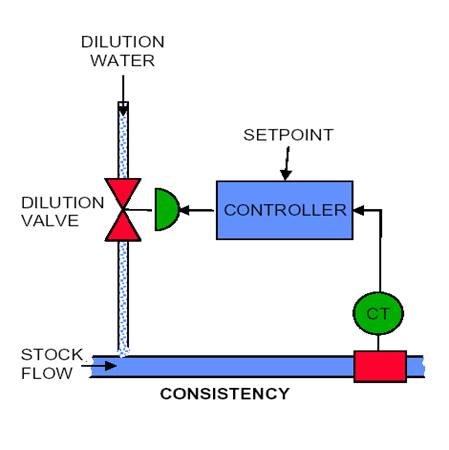

The consistency of the stock is also a contributing factor in the basis weight of the finished sheet.

As the consistency increases the sheet will get heavier. Attempts to maintain the consistency at the

desired level are made by adjusting the amount of dilution water added to the system.

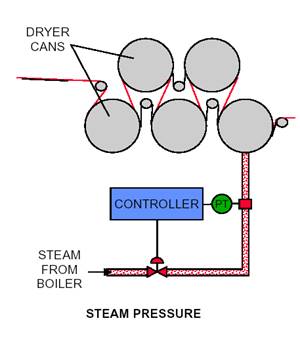

The amount of steam in the dryer cans determines the moisture of the finished sheet. For example; if the

sheet was too wet the operator would increase the setpoint of the steam pressure controller. This

action would cause the steam valve to open, putting more steam in the dryer cans - which would dry the

sheet.

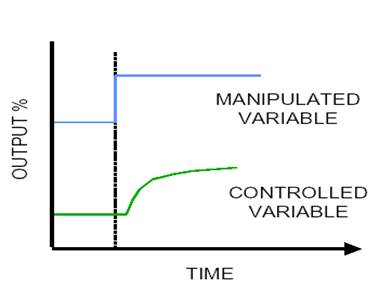

All processes exhibit some form of dynamic behavior. To study this behavior, it’s helpful to look at how a process responds to a step change in the manipulated

variable.

For Da Vinci, a DCS System is used whenever outputting to a final control element (e.g. valve). These systems have many options and can perform many functions. A common controller is the Proportional Integral Derivative (PID) controller. These are implemented in most DCS systems and as single

loop controllers.

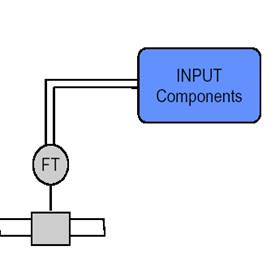

The purpose of the PID loop controller input is to convert process inputs into engineering units.

transmitter is connected to the input terminals.

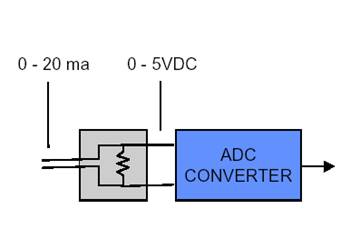

Many controllers utilize digital electronic

components. To process information from a field transmitter, the signal from the transmitter must be converted .

Many of the cascade controls used in paper mills

rely on inputs from Honeywell Measurex

scanners. Measurements provided by

these scanners include many sheet characteristics

such as: basis weight (mass), moisture , caliper,

color, formation, ash, smoothness, and opacity.

provide accurate “real-time” data that can be used to

adjust machine operation.

The result is improved machine efficiency and

higher product quality.

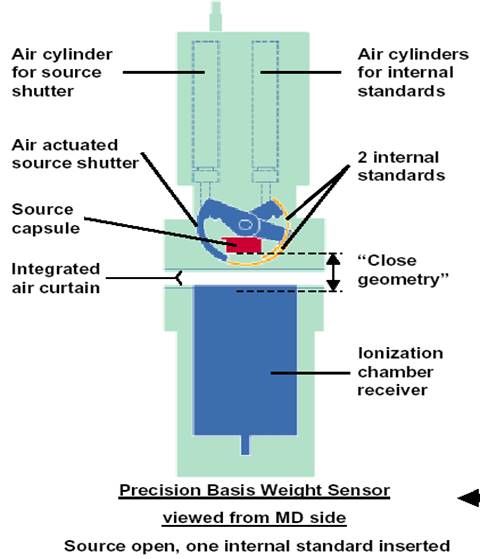

Accurate Ash /

measurement

• High signal-tono se i

tuned X-ray

tube

source

• Non-contacting

• Utilizes inputs from

Basis Weight and

Moisture gauges

• Compensation for

environmental

sources of error

– Air Temperature

– Z-axis Changes

– Dirt Buildup

• Fast Measurement Response

• High Resolution CD Profile

Measurement

• High Resolution MD Trend

Measurement

• Fast Profile Measurement

• High Frequency Process &

Quality Analysis

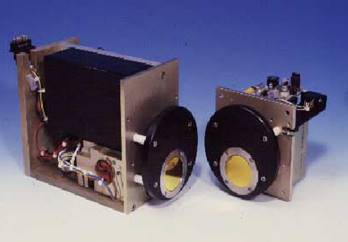

• HMX Basis Weight and Ash sensors utilize ionizing

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.