radiation sources.

– Basis Weight uses Krypton-85, an inert gas.

– If accidentally released, Krypton-85 dissipates quickly and

is rendered harmless when thoroughly dispersed.

– Some sensors at other mills contain solid sources, such

as Strontium or Americium, which must be treated with

greater care.

– Ash uses an X-ray tube which has its’ own 4kv power

supply. When the power is off, no X-rays are emitted.

• Radiation Indicators are located on each end of the

scanner frame.

– Red light indicates source shutters OPEN

– Green light indicates source shutters CLOSED

– Yellow light indicates Ash Power ON

• Safety Interlocks

– Hardware interlocks to force shutters closed if heads

accidentally become detached from scanner or are

damaged.

– Software interlocks to force shutters closed if heads are

separated; e.g. while cleaning sensors or if scan drive belt

breaks.

• Radiation Safety Checks are performed quarterly

by trained HMx personnel. Functionality of all

safety interlocks is tested.

Датчики Влажности:

• Magnetic

reluctance

principle

• Accuracy through

contacting

measurement

• Full sheet measurement

and signal processing

Contacting Design forAccurate Measurement

Pressurised Bellows:

• Heat and chemical resistant silicon rubber for long life

• Compresses sheet slightly for correlation to laboratory caliper

• Follows passline variation and sheet flutter

• Adjustable air pressure for optimum performance

Gimballed Skis:

• Rugged stainless steel construction

• Protects contacts and bellows

• Provides precise contact alignment

Caliper Measurement

• Oscillator frequency is proportional to the

length of the magnetic path,

– i.e. the gap between the sapphire and the ferrite

contacts

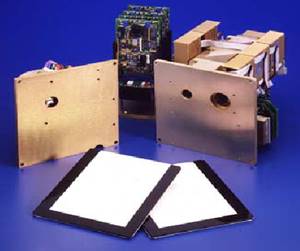

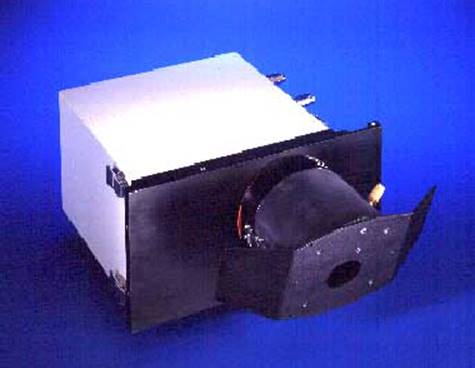

The Color Sensor measures the color, brightness, and fluorescence of a moving paper web by shining a specified illuminant on the web, then measuring the properties of

the reflected light. The Color Sensor consists of three functional modules:

• Source of illumination

• Receiver, light analyzer, and computer

• Standards and sheet backing. The three modules are contained in the two sensor heads. The illumination source,

receiver, light analyzer, and microcomputer are in one head (generally the upper head), and the standards and sheet backing are in the other.

Следующий датчик.

• High resolution CD profile

measurement

• High resolution MD trend

measurement

• Fast profile measurement

• High frequency process &

quality analysis• Fast measurement response

• Accurate measurement in

the presence of different

fillers, coatings, recycled

fibers and sheet temperature

variation

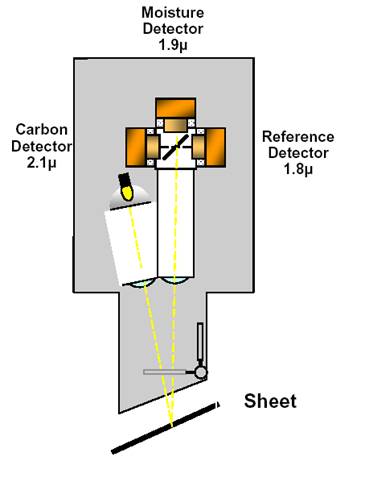

• Moisture-sensitive measurement at 1.9 microns varies with water content and basis weight

• Reference measurement at 1.8 microns varies with basis weight

Moisture Measurement – Reel

• Non-contacting, reflective measurement eliminates

breaks and sheet marking

• Low sensitivity to sheet flutter

• Insensitive to formation and non-uniform moisture

distribution

• Carbon correction permits accurate measurement in the presence of re-cycled fibre

• Small spot-size, fast response and unique signal

processing provides measurement to the edge of sheet

Moisture Measurement - Size Press

• Parallel processing.wavelength analysis

provides same-spot measurement of all channels

for:

– Formation-insensitivemeasurement

– Fast sensor response

• SingleCal™ calibration provides one calibration

group for most grades

• Carbon correction provides accurate moisture

measurement on nondeinked recycled stock.

Moisture Control Example

Moisture measurements from the scanner are compared to the moisture setpoint. Differences are acted on by the moisture controller and outputs are cascaded to the setpoint of the steam pressure controller. The steam

pressure controller then adjusts the steam valve.

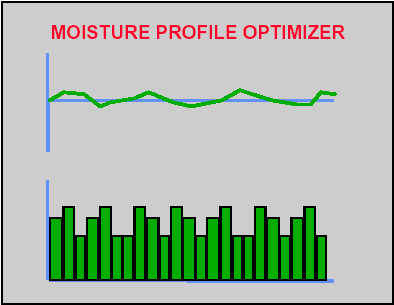

Moisture Profile Optimizer

Moisture profile control is a

flexible package that offers a

wide range of actuators including

Steamboxes and Aquatrol.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.