- The workpiece material is homogeneous, has no random property fluctuations;

- The Coulomb friction law was assumed. The friction ratios at rake and flank face were assumed to be equal;

- The slipping regions of MC were also neglected.

The FE model constraints has been discussed in detail. The external boundary of workpiece region was fixed and cutting force was applied to the master node of rigid tool boundary. The interaction between tool, chip and workpiece was provided by contact elements generated in the tool-chip and tool-workpiece interface.

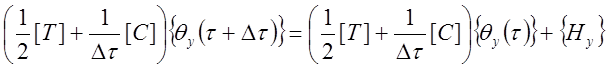

In the third subsection “Unsteady State Heattransfer Model”, the work equations based on Galerkin method for the domain of calculation and Crank-Nicholson method for time difference have been also discretized:

. (3)

. (3)

The time integration step ![]() has been determined in trial and

error simulation runs and was about 0.1 ms. In order to increase the solution

procedure stability the mesh thickening near tool-chip and tool-workpiece

interface has been used.

has been determined in trial and

error simulation runs and was about 0.1 ms. In order to increase the solution

procedure stability the mesh thickening near tool-chip and tool-workpiece

interface has been used.

The following assumptions have been made:

- Tool and chip shape is idealize. A flat flank face has been assumed;

- Heat source distributions are idealize;

- Material flow velocity distribution is idealize;

- Thermal material properties monotone varies with temperature;

- Dry cutting conditions are provided;

- No chatter vibration may appear.

It is important to note that all skiving features have been taken into account for proposed incremental solution procedure. The variation of cutting system geometry was simulated by approach described in the first section. The cutting of previously machined and heated surface that naturally takes palace under skiving has been also simulated. It was based on the cooling calculation by high-speed heat source equation and initial temperature modification according to the results gained.

According to the accepted solution procedure, the heattransfer problem has been concerned without any connection with deformation analysis. That is why material flow simulation was strongly needed and a conjugate procedure has been designed. The main idea consists in the new nodal initial temperature determination at every integration step based on the results obtained form the last step.

Since the dry cutting conditions have

been considered, the heat loss to the air is negligible. Therefore, in the

surface surrounded by air an insulated conditions of (![]() )

have been imposed. However, the more general conditions of coolant can be

simply taken into account. Along the workpiece bottom boundaries the work

material has been assumed to be at room temperature 20° since these boundaries are

sufficiently far from the primary deformation zone. Along the inlet boundary

the work material has been also assumed to be at room temperature during the

first revolution and at the specially determined temperature during the

following ones. Since the exit boundaries of the workpiece and the chip have

been extended sufficiently far from the cutting edge, the temperature gradients

normal to the boundaries have been expected to vanish. Therefore, an insulated

condition of (

)

have been imposed. However, the more general conditions of coolant can be

simply taken into account. Along the workpiece bottom boundaries the work

material has been assumed to be at room temperature 20° since these boundaries are

sufficiently far from the primary deformation zone. Along the inlet boundary

the work material has been also assumed to be at room temperature during the

first revolution and at the specially determined temperature during the

following ones. Since the exit boundaries of the workpiece and the chip have

been extended sufficiently far from the cutting edge, the temperature gradients

normal to the boundaries have been expected to vanish. Therefore, an insulated

condition of (![]() )on these boundaries has

been also assumed. Moreover, the temperature at the exit boundaries of the

workpiece was continuously accumulated for further initial temperature

calculation.

)on these boundaries has

been also assumed. Moreover, the temperature at the exit boundaries of the

workpiece was continuously accumulated for further initial temperature

calculation.

The initial temperature of certain node has been determined as the temperature of the material point, which node is currently coincident. It is clearly that it was in the other position at the last step. This position was interpolated according to assumed flow velocity distribution. The block diagram of described procedure has been also represented. An Usui scheme for interface nodal initial temperature computation under continuously remeshing has been also employed.

It is important to note that both deformation and heattransfer analysis are based on general FE-code. In this study NISA II/ DISPLAY III package has been chosen.

In the fourth subsection “Software Implementation”, a modular software package overview has been outlined. In order to reduce a time calculation it has been WATCOM C++ language coded and compiled under Windows 95. The package includes tool and workpiece mesh generation module, assembling and remeshing module, input and results visualization modules as well as NISA II translation module. All of these modules are controlled by data-control text file where the information about temporary files, cutting conditions, workpiece geometry and material properties as well as tool ones, required mesh have to be specified.

In the fifth subsection “Model Validation”, a validation of developed computation model has been carried out. A good correlation between published and obtained results has been shown both for deformation and heattransfer simulation under steady state cutting.

In order to validate FE model an analytical model for shear zone variables and cutting temperature computation under unsteady-state skiving conditions has been represented in the third section “Analytical Computational Model”. It is based on the equations mentioned in the first chapter and provides a description of cutting test results as well as prediction of cutting variables mentioned above. A in-depth explanation of the occupied ideas has been given. It is important to note that the most of skiving features have been also taken into account in represented analytical model. It has been achieved by new approaches to some coefficient determinations. The validation of this model has been also performed.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.