|

M |

obile terminals have become indispensable tools for information gathering. The

information handled by mobile terminals, which began with voice information,

have diversified into text, still and moving images. Recent technical advances

in cellular terminals, including multiple functions and high information

processing speed, make such diverse responses to information gathering

possible.

Although the size and weight of terminals practically remained unchanged, their RF circuits need to be smaller and lighter. To follow industry trends in terminal products, key parts such as SAW filters are required to be downsized and modularized. This article discusses efforts being made by makers to achieve such result.

Recently, attention has been focused on SAW duplexers. Together with

the advancements in communication processing speed of cellular terminals,

antenna switches are being replaced by duplexers in some communication systems,

and SAW duplexers are getting smaller and lighter than dielectric duplexers.

This feature of SAW duplexers addresses a market need.

Recently, attention has been focused on SAW duplexers. Together with

the advancements in communication processing speed of cellular terminals,

antenna switches are being replaced by duplexers in some communication systems,

and SAW duplexers are getting smaller and lighter than dielectric duplexers.

This feature of SAW duplexers addresses a market need.

However, in the past it was considered technically difficult for SAW duplexers to meet a high input power handling and ESD that are required of these communication systems. Murata Manufacturing Co., Ltd. has solved these problems by developing a film that can handle high input power and by optimizing the design of an IDT, making it possible for its SAW filters for CDMA800/TDMA800 systems to attain an input power handling of 50,000 hours at 1.2W and 50°C.

At present, the company is mass-producing SAW duplexers for

|

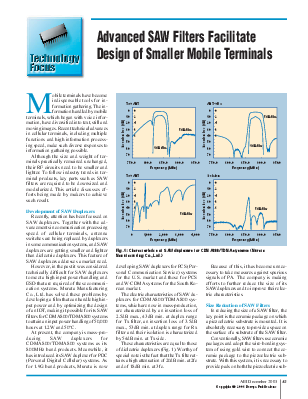

developing SAW duplexers for PCS (Personal Communication Service) systems for the U.S. market and those for PCS and W-CDMAsystems for the South Korean market. The electric characteristics of SAWduplexers for CDMA800/TDMA800 systems, which are now in mass-production, are characterized by an insertion loss of 2.5dB max., 43dB min. at duplex range for Tx filter, an insertion loss of 3.5dB max., 53dB min. at duplex range for Rx filter and their isolation is characterized by 54dB min. at Tx side. These characteristics are equal to those of dielectric duplexers (Fig. 1). Worthy of special note is the fact that the Tx filter attains a high attenuation of 20dB min. at 2fc |

Because of this, it has become unnecessary to take measures against spurious signals of PA. The company is making efforts to further reduce the size of its SAWduplexers and to improve their electric characteristics. Size Reduction of SAW Filters In reducing the size of a SAWfilter, the key point is the ceramic package on which a piezoelectric substrate is mounted. It is absolutely necessary to provide a space on the surface of a substrate of the SAWfilter. Conventionally, SAWfilters use ceramic packages and adopt the wire-bonding system of using gold wire to connect the ceramic package to the piezoelectric substrate. With this system, it is necessary to |

|

strate and the ceramic package, which is an obstacle to size reduction of SAW filters.

To solve this problem, the company adopted the flip-chip method of joining a

Others:

Grounding devices

Others:

Grounding devices

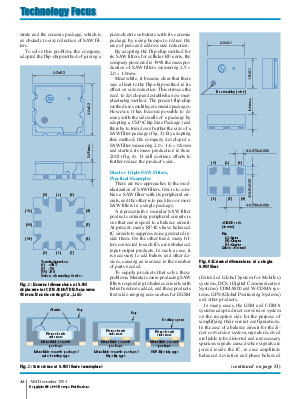

Fig. 2: External dimensions of SAW duplexers for CDMA800/TDMA systems

|

piezoelectric substrate with its ceramic package by using bumps to reduce the area of pads and address size reduction. By adopting the flip-chip method for its SAW filters for cellular RF units, the company pioneered in 1998 the mass production of SAW filters measuring 2.5 × 2.0 × 1.0mm.

Meanwhile, it became clear that there was a limit to the flip-chip

method in its effect on size reduction. This stresses the need to develop and

establish a new manufacturing method. The present flip-chip method uses

multilayer ceramic packages. However, it has become possible to do away with

the sidewalls of a package by adopting a CSP (Chip Size Package) and thereby to

trim down further the size of a SAW filter package (Fig. 3). By adopting this

method, the company developed a SAW filter measuring 2.0 × 1.6 × 0.8mm and started its

mass-production in June 2003 (Fig. 4). It will continue efforts to further

reduce the product’s size.

Meanwhile, it became clear that there was a limit to the flip-chip

method in its effect on size reduction. This stresses the need to develop and

establish a new manufacturing method. The present flip-chip method uses

multilayer ceramic packages. However, it has become possible to do away with

the sidewalls of a package by adopting a CSP (Chip Size Package) and thereby to

trim down further the size of a SAW filter package (Fig. 3). By adopting this

method, the company developed a SAW filter measuring 2.0 × 1.6 × 0.8mm and started its

mass-production in June 2003 (Fig. 4). It will continue efforts to further

reduce the product’s size.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.