INFORMATION SYSTEM DESIGNING FOR TUNING OF WORK PROCESS CONTROL ALGORITHM OF A DIESEL ENGINE

The author: Zhukov P.T.

North-West State Technical

University (S-Peterburg, Russia )

Abstract

The increasing requirements for ecological and economical parameters of a vehicle have demanded to introduce better and more advanced engine control system . Modern automotive engines are controlled by electronic control system, that allows to monitor engine operating conditions, utilizing information from the input sensors.

To tune control algorithms and calibrate data of electronic control system , the information system ( the soft-hardware complex) is widely used at present.

The objective of this article is to design the information system which allows to find the most useful information from all information variety, and then to optimize parameters of work process control system .To provide accurate control algorithm , the applied software uses simulating animation of mixture formation.

Introduction

For the last years the significant changes in design of a vehicle have taken place. The increasing requirements for ecological and economical parameters of a vehicle have demanded to introduce better and more advanced engine control system .

Modern automotive engines are controlled by electronic control system, that allows to monitor engine operating conditions, utilizing information from the input sensors.

The heart of electronic control system is the ECU ( Electronic Control Unit ) . It has capability to receive and process information , and make operating decisions about the fuel system condition.

The engine work process control is a kind of information processing. Information from sensors to actuators of control system is different both in characteristics and importance. In this case it becomes very important to find the most useful information from all information variety, and then to optimize parameters of work process control system . Therefore the problems, connected with designing work process control system of an engine are closely connected with a type of information .

To provide accurate fuel mass and fuel injection duration for each cylinder individually , the ECU uses a program ( an algorithm ) , which determinates a basic injection volume based on different factors such as fuel mixture , shaft speed, current temperature , pressure of air supercharging, air consumption , correcting coefficients .

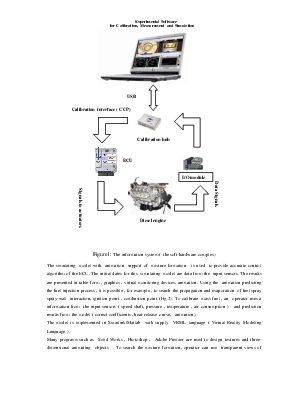

To tune control algorithms and calibrate data of electronic control system , the information system ( the soft-hardware complex) is widely used at present (Fig.1). Information system is a system in which operator can choose current algorithm of control and manage by adjustments and parameters of work processes.

Main results

In this article I can present the an information system with simulating support , that allows to calibrate and measure parameters by means of interface Can Calibration Protocol ( CCP). The Calibration

interface can be connected directly to the host PC via USB ( www. Dspace.com).

It the system can be divided into two parts (Fig.1) :

1) The hardware ( the ECU, the Calibration hub, the input/output module, the host PC;

2) the applied software which provides a graphical user interface for handling calibration , measurement tasks and modeling tasks. The software is the heart of the calibration system.

![]()

|

|

|

|

|||

|

|||

|

Data Signals |

|

||||

|

||||

|

Signals to actuators |

Figure1: The information system ( the soft-hardware complex)

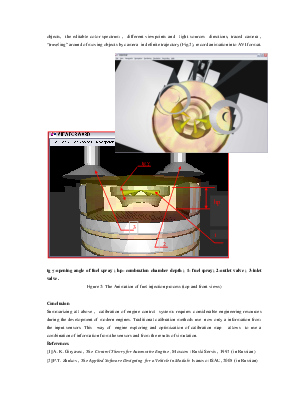

The simulating model with animation support of mixture formation is used to provide accurate control algorithm of the ECU. The initial dates for this simulating model are data from the input sensors. The results are presented in table-form , graphics , virtual monitoring devices, animation. Using the animation predicting the fuel injection process , it is possible , for example , to search the propagation and evaporation of fuel spray spray-wall interaction, ignition point , combustion point (Fig.2). To calibrate mass fuel , an operator uses a information from the input sensors ( speed shaft, pressure , temperature , air consumption ) and prediction results from the model ( correct coefficients , heat-release curve, animation).

The model is implemented in Simulink/Matlab with supply VRML language ( Virtual Reality Modeling Language ) .

Many programs such as Solid Works , Photoshop , Adobe Premier are used to design textures and three-dimensional animating objects . To search the mixture formation, operator can use transparent views of objects, the editable color spectrum , different viewpoints and light sources directions, traced camera , “traveling” around of moving objects by camera in definite trajectory (Fig.2), record animation into AVI format.

|

Reference

tg γ-opening angle of fuel spray ; hp- combustion chamber depth ; 1- fuel spray; 2-outlet valve ; 3-inlet valve .

Figure 2: The Animation of fuel injection process (top and front views)

Conclusion

Summarizing all above , calibration of engine control systems requires considerable engineering resources during the development of modern engines. Traditional calibration methods use now only a information from the input sensors. This way of engine exploring and optimization of calibration map allows to use a combination of information from the sensors and from the results of simulation.

References

[1] A. K. Giryavec , The Control Theory for Automotive Engine ,Moscow : Ruski Servis , 1997 ( in Russian )

[2] P.T. Zhukov , The Applied Software Designing for a Vehicle in Matlab: Ivanovo :ISAU, 2005 ( in Russian)

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.