Senior management makes decisions regarding the progress and status of an investment program at critical milestones (decision points) to ensure proper transition of the program throughout the AMS lifecycle. In support of decision-making, V&V reduces program risk by ensuring that the information used to make the decision is accurate and dependable. Each decision point requires the development of verified and validated work products that provide information about the progress and status of the program and product being developed.

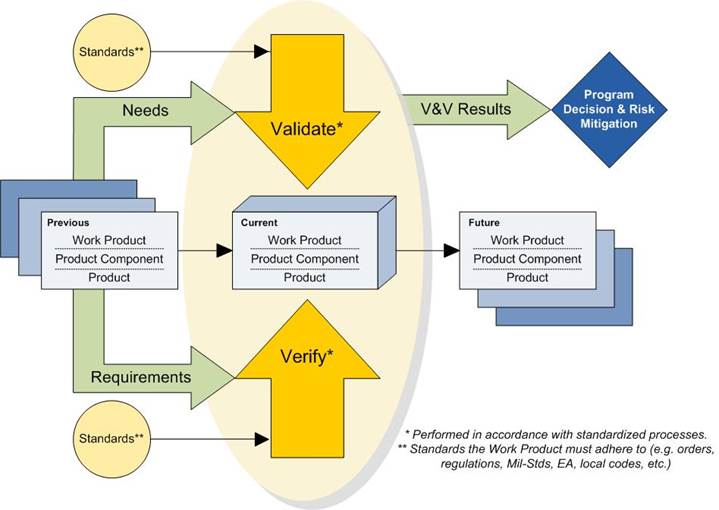

Figure 2 depicts a generic flow of how V&V is applied. Current work products, products and product components are validated against needs and verified against requirements, as identified in previous work products, products, and product components. As an example, a system specification would be validated against the program requirements document, which is a higher-level specification that defines mission needs in the form of operational requirements. The system specification is verified against applicable standards and templates that define content and format. The results of V&V support key program decisions and risk mitigation. Each work product then becomes the basis for V&V of future work products (or the final product). This process puts great emphasis on work products developed early in the AMS lifecycle such as gap analyses, concept of operation documents, and requirements documents. These work products must be validated to ensure that the right product is built.

Figure 2. Basic Application of V&V

V&V planning must be incorporated into the appropriate sections of existing program planning documents throughout the lifecycle of the product. These planning documents include, but are not limited to, the plan for Concept and Requirements Definition, plans for initial and final Investment Analysis, the Implementation Strategy and Planning Document (ISPD), the Program Management Plan, and the Quality Assurance Plan. These documents must incorporate the V&V planning elements listed below as they apply to each document:

1) Description of V&V methods

2) Identification of work products, product components, and products to be verified and/or validated

3) Identification of criteria to be used in the verification and validation of work products, product components, and products

4) Identification of metrics and reports required to track and document V&V events and activities

5) Definition of roles and responsibilities for V&V events and activities

6) Description of tools, models, prototypes, laboratories, and simulators required to support V&V events and activities

7) Identification of processes and standards to be used for V&V of work products, products, and product components for each phase of the program, such as:

a) Systems Engineering Manual

b) Operational Concept Validation Strategy Document

c) Test and Evaluation Handbook

d) Test and Evaluation Process Guide

8) Identification of training required for successful completion of V&V events and activities

Further planning guidance can be found at the following websites:

1) FAA Acquisition System Toolset (FAST) website:

http://fast.faa.gov/

2) Acquisition Practices website: https://employees.faa.gov/org/linebusiness/ato/operations/technical_operations/best_practices/

3) Test Standards Board (TSB) website: https://ksn.faa.gov/km/ajpterep/default.aspx

The purpose and methods for verifying and validating work products, product components, and products are described in the following paragraphs.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.