FAA AMS LIFECYCLE

VERIFICATION AND VALIDATION

GUIDELINES

Version 1.0

December 2, 2009

TABLE OF CONTENTS

1 Introduction.. 1

1.1 Scope. 1

1.2 V&V Terms and Definitions. 1

1.2.1 V&V Terms. 1

1.2.2 V&V Definitions. 2

1.3 V&V Philosophy. 3

2 V&V Implementation Guidance.. 5

2.1 V&V Planning. 5

2.2 Performing V&V.. 6

2.2.1 V&V of Work Products. 6

2.2.2 V&V of Products and Product Components. 7

2.3 V&V Reporting. 9

2.4 V&V Decision Support. 9

3 V&V Approach in the AMS Lifecycle.. 10

3.1 V&V in Research and Systems Analysis. 12

3.2 V&V in Mission Analysis. 12

3.2.1 Corporate Mission Analysis and Service Analysis. 12

3.2.2 Concept and Requirements Definition. 14

3.3 V&V in Investment Analysis. 16

3.3.1 Initial Investment Analysis. 16

3.3.2 Final Investment Analysis. 19

3.4 V&V in Solution Implementation. 24

3.5 V&V in In-Service Management. 28

APPENDIX A. Acronyms. 32

LIST OF FIGURES

Figure 1. Work Product/Product Component/Product Relationships. 2

Figure 2. Basic Application of V&V.. 4

Figure 3. AMS Lifecycle Primary V&V Activities. 11

LIST OF TABLES

Table 1. V&V in Corporate Mission Analysis and Service Analysis. 13

Table 2. V&V in Concept and Requirements Definition. 15

Table 3. V&V in Initial Investment Analysis. 17

Table 4. V&V in Final Investment Analysis. 20

Table 5. V&V in Solution Implementation. 25

Table 6. V&V in In-Service Management 29

This document guides the application of Verification and Validation (V&V) policies across the Federal Aviation Administration (FAA) Acquisition Management System (AMS) lifecycle by defining terminology, illustrating how to accomplish V&V, and describing its application in each phase of the AMS lifecycle as defined in the FAA Acquisition Management Policy.

This guidance document supports research, analysis, program management, and test activities for planning, performing, reporting, and decision support relating to V&V activities.

This document will be updated as better practices are identified and new lessons are learned. The latest version is available on the FAA Acquisition Practices website: https://employees.faa.gov/org/linebusiness/ato/operations/technical_operations/best_practices/.

V&V is a disciplined approach to assessing select products -- along with associated product components and work products -- throughout the lifecycle of a system, service, facility, or operational change. The conduct of V&V ensures that a quality product is built and that it satisfies operational requirements and service needs. The order and significance of verification versus validation may change throughout the lifecycle based on the state of the mission definition, operational concept, requirements, product development, and product.

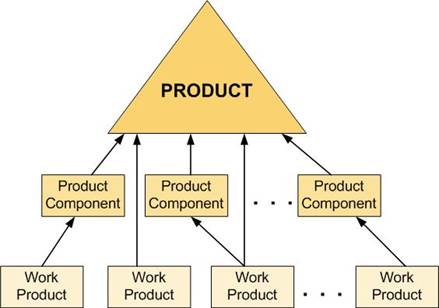

V&V is performed on government and contractor work products, product components and products, and is required to be done by government and contractor organizations. Work products, product components, and products may be subject to V&V more than once during their lifecycle if modifications or additional levels of V&V are required. The definitions of work product, product component, and product are:

1) Work Product. A work product in various forms represents, defines, or directs the final product. This can include documents, processes, procedures, designs, descriptions, specifications, simulations, models, prototypes, and contracts.

2) Product Component. A product component is a lower-level part, element, or module of the product. Product components are integrated to produce the product. There may be multiple levels of product components.

3) Product. The final or end system, service, facility, or operational change that is intended for delivery to a customer or end user.

Figure 1 depicts the relationship between work products, product components, and products. The early phases of the AMS lifecycle will generate a number of work products which must be verified and validated, such as concepts of operations and program requirements documents that define and direct the development of the product components and the final product. The first elements of the product available during development that must be verified and validated are product components. In turn, product components are integrated to generate the final product to be verified and validated.

Figure 1. Work Product/Product Component/Product Relationships

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.