|

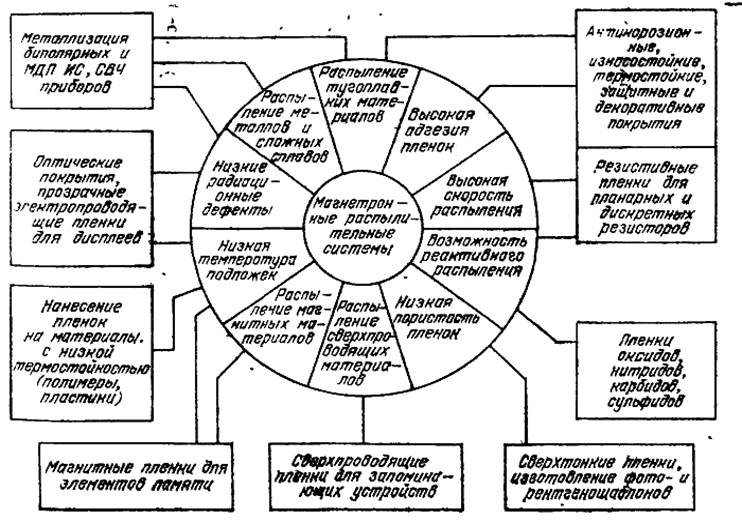

Figure 1 Prominent features and scopes of magnetron sputtering systems

|

Characteristic |

Electron beam evaporation |

High-frequency sputtering |

Magnetron sputtering |

|

Process of particle generation |

|||

|

Energy source |

An electron beam gun |

The high-frequency glow discharge |

Magnetron glow discharge |

|

Way of substance generation |

electron bombardment |

ion bombardment |

ion bombardment |

|

Energy carriers |

Electrons |

Ions |

Ions |

|

Energy of bombarding particles, keV |

10…30 |

0.1…3 |

0.3…0.7 |

|

Average specific capacity, W/sm2 |

(0.2…2)·103 |

2·101 |

2·102 |

|

Maximal specific capacity, W/sm2 |

104…105 |

102 |

5·102…103 |

|

Average density of a current, A/sm2 |

(0.5…5)·10-1 |

3·10-3 |

3·10-1 |

|

Source of particles |

|||

|

Specific speed of evaporation / sputtering, g·sm-2·s-1 |

(2…20)·10-3 |

(2…20)·10-7 |

(4…40)·10-3 |

|

Efficiency of process, g·Joule-1 |

3·10-6 |

6·10-7 |

3·10-6 |

|

Energy of generated particles, eV |

0.1…0.2 |

10…200 |

10…20 |

|

Process of coating precipitation |

|||

|

Precipitation speed, nm/ sec |

10…60 |

0.3…3 |

10…60 |

|

Energy of precipitable particles, eV |

0.1…0.2 |

0.2…20 |

0.2…10 |

|

Working pressure, Pa |

10-4 |

0.5…2 |

0.2…10 |

|

Specific capacity, dissipated on a substrate, Wt/sm-2 |

0.1 |

5 |

1 |

|

Substrate heating during precipitation, K |

To 770 |

To 670 |

To 370 |

|

Source of radiation influence on a substrate |

X-ray radiation (electrons) |

Secondary electrons (x-ray radiation, photons, ions) |

Photons (ions) |

Thus, it is clear, that magnetron sputtering systems as the method of reception of thin-film coverings has a number of advantages over other vacuum methods that causes their wide application and prospect of development. Taking into account prospect and applicability of this method, in this work the analysis of heat modes of products when precipitation of coatings with the help of magnetron sputtering systems is carried out.

The purpose of work is to carry out the analysis of the processes influencing a thermal mode of a product when drawing coverings with the help of magnetron sputtering systems and to offer the technique of a product heat mode estimation when drawing coatings with use of magnetron sputtering systems.

Object of research are the processes, being sources of heat in magnetron sputtering systems.

Tasks of work:

Carrying out of the work review of domestic and foreign authors on a theme of work;

The analysis of the review materials and specification of the problem put by;

Development of the technique of a product heat mode estimation when drawing coatings in magnetron sputtering systems;

Creation of the software for realization of the developed technique;

Comparison of carried out estimations with experimental data.

At present magnetron sputtering systems have wide application. However the method is mastered not long ago, there is no enough full and proved technique of definition of a product heat mode when drawing coatings with use of magnetron sputtering systems. More often the heat mode of a product is determined as a result of lines of experiments. Therefore there is a requirement to create a simple and universal technique of a product heat mode estimation when drawing coatings with use of magnetron sputtering systems.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.