4) For calculations of the dispersion coefficient of materials dependence on gas pressure and distances to the surface of condensation in some cases F.Penning and D.Maubs formulas are used. F.Penning and D.Maubs have assumed, that for the sprayed atoms it is possible to use the expression received В. by V. de Gott and G.Poze for the description of diffusion in gas of evaporating atoms between two infinite planes [46]. The formula provides equality of average kinetic energies of sprayed particles Ер and atoms of gas Еg:

(5.16)

(5.16)

where Yр - the real dispersion coefficient of the material without taking into account influence of outdiffusion; λр0{1} - average length of free path of the sprayed atoms at pressure р=1 Pa and temperature 273 To; ро =273р/Т - the pressure of gas resulted to Т=273 To;d - distance from the target up to the surface of condensation. (5.16) dependences Yр of copper designed on the formula and nickel from product pod in comparison with experimental data give more than on the order the underestimated values pod for the beginning to return diffusion (fig. 5.16) [6]. Therefore the formula (5.16) cannot be used for engineering calculations at a choice of a technological mode of dispersion and geometry SS that shows necessity of development of new physical model of process of carry of the sprayed particles for the environment of working gas.

5) Taking into account an initial direction of movement of the sprayed atoms in gas dependence of the dispersion coefficient on product p0d can be written down at p0d <LК (1) as

Yp(p)=Yp, (5.17)

and at p0d> Lk as

Yp(p)=Yp2,3λр0(1)/[2,3λр0(1)+р0d-LK(1)], (5.18)

where р0 =273р/Т - the pressure of gas resulted to Т=273 To;d - distance from the target up to the surface of condensation;LK(1) - average length of the directed path at individual gas pressure [21].

6) At mа <mg the basic process determining returning of particles on the target in area pod<.LK (1) is outdispersion. Dependence of the dispersion coefficient on pressure of gas under condition of isotropy can be submitted as

![]() . (5.19)

. (5.19)

In areapod> LK (1) sprayed particles come back to the target due to outdispersion, and due to outdiffusion, and dependence of the dispersion coefficient on pressure of gas looks like

, (5.20)

, (5.20)

where mа - weight of atoms of the sprayed material, mg - weight of atoms of working gas [21].

7) In various sources there is a plenty of experimental data on values of the dispersion coefficients for various materials. These data are widely used at carrying out of various calculations. Also at presence of experimental data there is an opportunity of their approximation and description of the dependence of the dispersion coefficient on the bombarding ions energy by the simple algebraic equation, than equations submitted above.

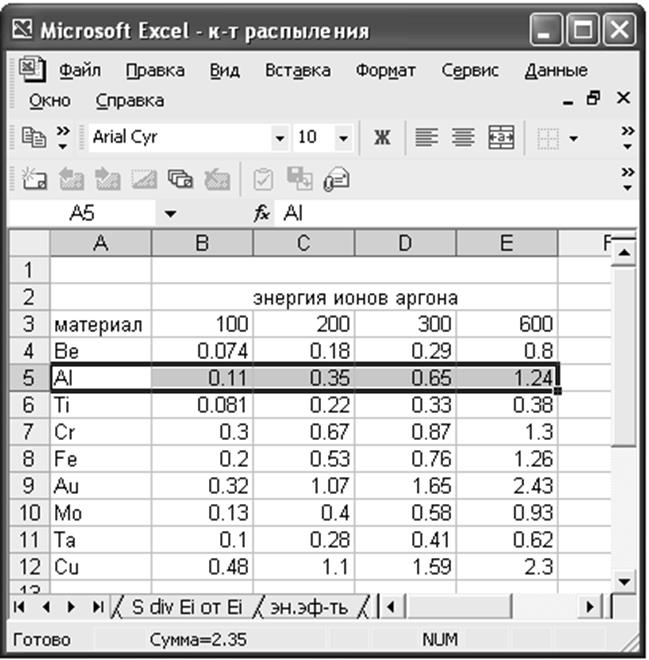

On the basis of available experimental data it is possible to create a database. There is an opportunity to determine exact value of the dispersion coefficient depending on energy of bombarding ions with help of it. For this purpose it is possible to use program environment MS Excel. In a file it is possible to write down the available data on the dispersion coefficients for a range of ion energies interesting to us. Then on these values one can construct graphic dependences.

Then on the received graphic dependences using MS Excel were received approximated dependences for each lines of the data. Let’s consider a technique of carrying out of process by the example of definition of the approximated curve for the cathode - target material from copper and titan when bombarding by ions of argon. In figure 5.18 the fragment of the database described above is submitted. The graphic dependence of the dispersion coefficient for copper and titan is constructed on the values of this database (fig. 5.19).

Figure 5.18 Window form MS Excel: a fragment of a database of values of the dispersion coefficients of various materials.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.