DETERMINING OF THE MATHEMATICAL MODEL

HEATER SYSTEMS OF THE STEM OF SHAFT

Arthur V. Marfyn

Belarusian State Technological University

Sverdlova av. 13a, Minsk, 220050, BELARUS

Tel: 810 375 17 226-14-32, E-mail: AMARFYN@YAHOO.COM

ABSTRACT

Object of research in the given job became system of heating of a trunk of shaft. The critical analysis on earlier existing control system of technological process is imaged. The problems arising at realization of a control system are considered.

On summaries of an obtained model, the automatic control system has been synthesized. Thus qualitative applying of mathematical numerical methods in the chemical industry is displayed.

INTRODUCTION

To present day the majority from used on a line of heating of engineering tools of the temperature control, the flow of heat-transfer agent are not adjusted to operation in closed automatic control system with the COMPUTER.

The aim of operation - to show on a concrete instance possibility of implementation of the design on upgrading the technological object, by a heading current technologies, outcome of that became economic efficiency, at the expense of saving power.

The analysis of system of automation of technological process

The description of technological operating modes of process.

The given technological process represents system of heating of shaft of stack of 4th Mine of Republican unitary enterprise "Production Amalgamation "Belaruskali".

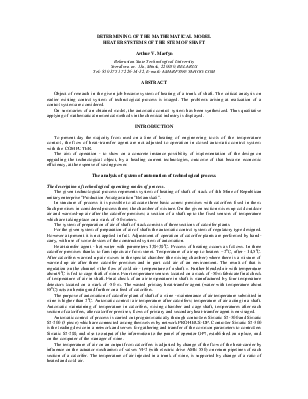

In structure of process it is possible to allocate three basic zones: premises with calorifers fixed in them. Such premises in considered process three; the chamber of mixture. On the given section mixes up cold outdoor air and warmed-up air after the calorifer premises; a section of a shaft up to the fixed sensors of temperature which are taking place on a mark of -50 meters.

The system of preparation of air of shaft of stack consists of three sections of calorifer plants.

For the given system of preparation of air of shafts the automatic control system of regulatory type designed. However at present it is not applied in full. Adjustment of operation of calorifer plants are performed by hand-carry, with use of some devices of the constructed system of automation.

Heat-transfer agent - hot water with parameters 130÷300С. Process of heating occurs as follows. In three calorifer premises thanks to fans injects air from street. Temperature of air up to heaters --20С, after - 14,50С. After calorifers warmed up air moves in the special chamber (the mixing chamber) where there is a mixture of warmed up air after three calorifer premises and in part cold air of an environment. The result of that is regulation on the channel « the flow of cold air - temperature of a shaft ». Further blended air with temperature about 90С is fed to cage shaft of mine. Four temperature sensors located on a mark of -50m fabricate final check of temperature of air in shaft. Final check of an air temperature in shaft is manufactured by four temperature detectors located on a mark of -50 m. The wasted primary heat-transfer agent (water with temperature about 650С) acts on heating and further on a feed of calorifers.

The purpose of automation of calorifer plant of shaft of a mine - maintenance of air temperature submitted in mine is higher than 20С. Automatic control: air temperature after calorifers; temperature of air acting in a shaft. Automatic maintaining of temperature in calorifers, mixing chamber and cage shaft, temperatures after each section of calorifers, after calorifer premises, flows of primary and secondary heat-transfer agent is envisaged.

Automatic control of process is carried out programmatically through controllers Simatic S7-300 and Simatic S7-200 (3 piece) which are connected among themselves by network PROFIBUS-DP. Controller Simatic S7-300 is the leading device in a network and serves for gathering and transfer of the common parameters to controllers Simatic S7-200, and also to output of the information to the panel of operator ОР7, established on a place, and on the computer of the manager of mine.

The temperature of air on an output from calorifers is adjusted by change of the flow of the heat-carrier by influence on the actuator mechanism of valves VF2 (with electric drive AME 550) on return pipelines of each section of a calorifer. The temperature of air injected in a trunk of mine, is supported by change of a ratio of heated and cold air.

MAIN RESULTS

Development of mathematical model of control system

The analysis of manufacturing process as control object

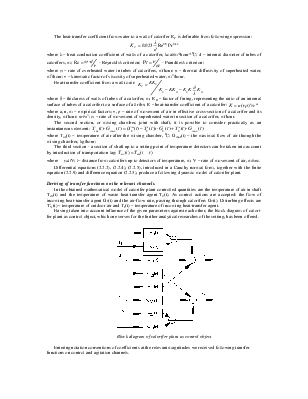

Dynamics of processes in calorifer plant we shall understand time history of an air temperature in cage shaft and the temperatures of waste primary heat-transfer agent caused by fluctuations of flow and temperature acting primary (water) and secondary (air) of heat-transfer agent.

The simplified mathematical model of calorifer plant can be received if to take some assumptions idealizing process of a heat-away: transfer of heat to the heated air is carried out only by convection; specific heat capacities and density of a metal wall of calorifers and warmed up air are constant in the field of considered temperatures; temperature in cross-section of a metal wall of calorifers, and also factors of heat dissipations from water to a metal wall and from last to air, are equal to all surface of heat exchange.

Development of a mathematical model of manufacturing process.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.