Specifications C27 and C32 Engines for Caterpillar Built Machines

|

Media Number --07 |

Publication Date -01/12/2008 |

Date Updated -22/12/2008 |

|

|

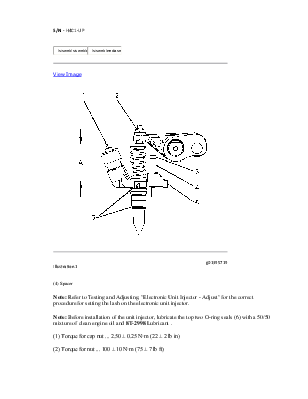

SMCS - 1290 Part Number - 255-8001 S/N - JXP1-UP Part Number - 260-9631 S/N - DLS1-UP Part Number - 260-9631 S/N - 5301-UP Part Number - 255-8001 S/N - LWA1-UP Part Number - 260-9631 S/N - LWA1-UP Part Number - 255-8001 S/N - EXD1-UP Part Number - 260-9631 S/N - EXD1-UP Part Number - 260-9631 S/N - TPB1-UP Part Number - 255-8001 S/N - EYG1-UP Part Number - 255-8001 S/N - H4C1-UP Part Number - 255-8001 S/N - Z9K1-UP Part Number - 260-9631 S/N - JRP1-UP Part Number - 260-9631 S/N - JXP1-UP Part Number - 255-8001 S/N - 5301-UP Part Number - 260-9631 S/N - GEB1-UP Part Number - 255-8001 S/N - EED1-UP Part Number - 260-9631 S/N - EED1-UP Part Number - 260-9631 S/N - EYG1-UP Part Number - 260-9631 S/N - Z9K1-UP Part Number - 260-9631 S/N - BTW1-UP Part Number - 260-9631 S/N - BWX1-UP Part Number - 255-8001 S/N - 2211-UP Part Number - 260-9631 S/N - 2211-UP Part Number - 260-9631 S/N - RJG1-UP Part Number - 255-8001 S/N - JRP1-UP Part Number - 255-8001 S/N - DLS1-UP Part Number - 260-9631 S/N - JNW1-UP Part Number - 260-9631 S/N - H4C1-UP

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.