Disassembly and

Assembly

784C, 785C and 785C HAA Off-Highway Truck/Tractors Power Train

|

Media

Number --05

|

Publication Date -01/08/2004

|

Date Updated -12/08/2004

|

Transmission Planetary and

Transfer Gears - Install

SMCS

-

-012

Installation

Procedure

|

Table 1

|

|

Required Tools

|

|

Tool

|

Part Number

|

Part Description

|

Qty

|

|

A

|

6V-0006

|

Governor

Pliers

|

1

|

|

B

|

6V-3145

|

Load

Leveler

|

1

|

Note: Cleanliness is an

important factor. Before the installation procedure, all parts should be

thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths

or rags should not be used to dry parts. Lint may be deposited on the parts

which may cause later trouble.

- Check all of the O-ring seals and the

components for wear or damage. Replace the components, if necessary.

- Lubricate all of the O-ring seals

lightly with the lubricant that is being sealed.

|

|

|

View Image

|

|

|

|

Illustration

1

|

g00568837

|

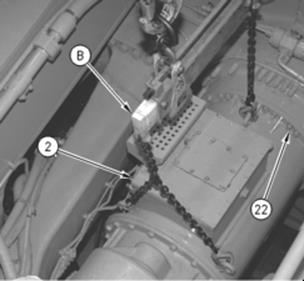

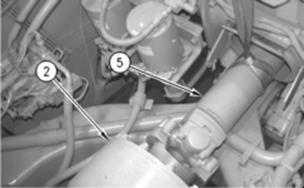

- Install Tool (B) to planetary

transmission and transfer gear (2). Attach Tool (B) to a suitable lifting

device and a hoist.

- Use Tool (B) and the hoist in order to

position planetary transmission and transfer gear (2) for installation to

the differential carrier assembly. The weight of planetary transmission

and transfer gear (2) is 2313 kg (5100 lb).

- Use 24 bolts (22) and the hard

washers in order to install planetary transmission and transfer gear (2)

and the O-ring seal to the differential carrier assembly. Tighten 24 bolts

(22) to a torque of 430 ± 60 N·m (317.15 ± 44.25 lb ft).

- Remove Tool (B) from planetary

transmission and transfer gear (2) .

|

|

|

View Image

|

|

|

|

Illustration

2

|

g00568835

|

- Connect hose assembly (21) .

- Connect hose assembly (20) .

|

|

|

View Image

|

|

|

|

Illustration

3

|

g00568833

|

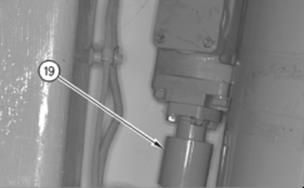

- Connect hose assembly (19) to the

magnetic screen housing.

|

|

|

View Image

|

|

|

|

Illustration

4

|

g00568770

|

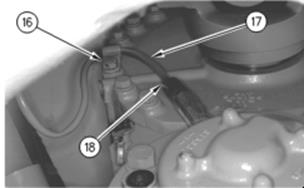

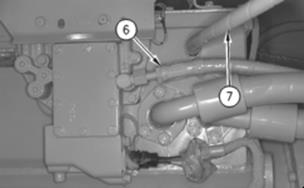

- Use Tool (A) (not shown) in order to

connect wire harness (17) to the transmission speed sensor at the

electrical connection.

- Install lockwire (18) into the

electrical connector of wire harness (17) .

Note: Install the

lockwire in the next endbell hole in the clockwise direction.

- Install bolt (16), the washer and the

clip to the transfer case assembly. Tighten bolt (16) to a torque of 135 ±

20 N·m (100 ± 15 lb ft).

|

|

|

View Image

|

|

|

|

Illustration

5

|

g00568769

|

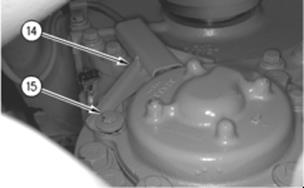

- Use two bolts (15), the washers, and

the two grommets in order to install guard (14) to the speed sensor

housing.

|

|

|

View Image

|

|

|

|

Illustration

6

|

g00567637

|

|

|

|

View Image

|

|

|

|

Illustration

7

|

g00567635

|

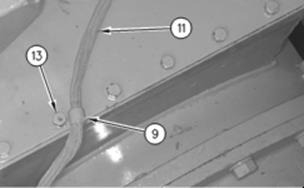

- Use bolt (13) in order to install

clip (9) .

- Connect wire harness (11) at the

three electrical connections, as shown.

|

|

|

View Image

|

|

|

|

Illustration

8

|

g00567593

|

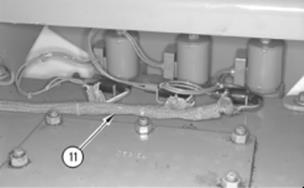

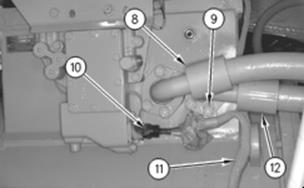

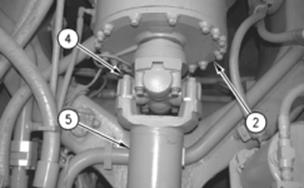

- Use Tool (A) (not shown) in order to

connect wire harness (11) to the transmission position sensor at the

electrical connection.

- Install lockwire (10) into the

electrical connection of wire harness (11) .

Note: Install the

lockwire in the next endbell hole in the clockwise direction.

- Connect hose assembly (12) and two

clips (9), as shown.

- Connect hose assembly (8) .

|

|

|

View Image

|

|

|

|

Illustration

9

|

g00567592

|

- Connect hose assembly (7) .

- Connect hose assembly (6) .

|

|

|

View Image

|

|

|

|

Illustration

10

|

g00567587

|

|

|

|

View Image

|

|

|

|

Illustration

11

|

g00567583

|

- Attach a suitable lifting sling

around drive shaft (5). Attach the lifting sling to a hoist.

Note: Attach the lifting

sling to the center point of drive shaft (5). This will help to

balance drive shaft (5) .

- Use the hoist and the lifting sling

in order to position drive shaft (5) for installation.

- Use a suitable pry bar in order to

extend drive shaft (5). Use four new bolts (4) in order to connect drive

shaft (5) to the yoke of planetary transmission and transfer gear (2).

Tighten four bolts (4) to a torque of 550 ± 20 N·m (405.7 ± 14.8 lb ft).

- Remove the lifting sling from drive

shaft (5) .

|

|

|

View Image

|

|

|

|

Illustration

12

|

g00567576

|

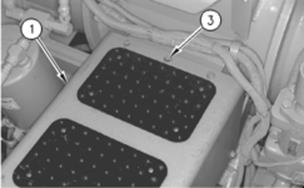

- Position guard assembly (1) onto the

frame assembly. Use five bolts (3) and the hard washers in order to

install guard assembly (1) to the frame assembly.

- Fill the differential and final drive

with hydraulic oil to the correct level. Refer to Operation and

Maintenance Manual, SEBU7173, "Differential and Final Drive Oil -

Change" for the correct procedure.

- Fill the transmission system with

hydraulic oil to the correct level. Refer to Operation and Maintenance

Manual, SEBU7173, " Transmission Tank Oil - Change" for the

correct procedure.

,,

End By:

- Remove the retaining cable. Refer to

Disassembly and AssemblySENR1500, "Body Retaining Cable - Remove and

Install".

- Remove the wheel chocks. Refer to

Disassembly and AssemblySENR1500, "Wheel Chocks (Front and Rear) -

Remove and Install".