GRABOWSKI et al.: DEVELOPMENT OF A HIGH-CURRENT LOW-INDUCTANCE CROWBAR SWITCH 1913

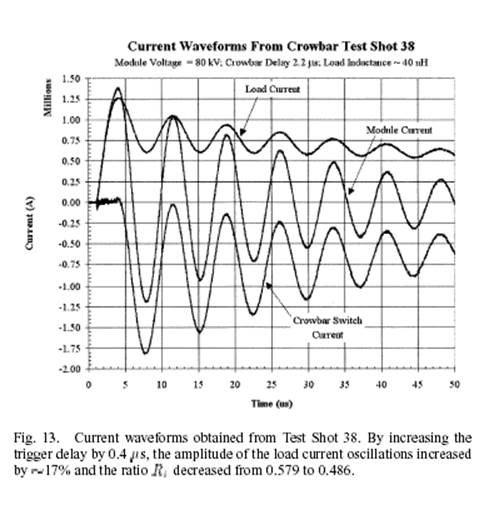

Fig. 13. Current waveforms obtained from Test Shot 38. By increasing the

trigger delay by 0.4 _s, the amplitude of the load current oscillations increased

by _17% and the ratio R decreased from 0.579 to 0.486.

Fig. 14. Data for peak load current, load current at the first minimum, and the

ratio of I =I (=R ) taken from several shots with varying crowbar

trigger delay times. The load inductance for these test shots was 40 nH, and the

composite charge voltagewas 80 kV. The amplitude of the oscillations increased

as the crowbar trigger time approached the time of the current peak, while the

value of the peak current remained relatively unchanged.

Since the peak load current does not increase greatly as the

crowbar trigger time is moved closer to the time of current peak,

whereas the oscillations continue to grow, there is no advantage

to setting the crowbar trigger delay for longer than 1.8 s.

Delay times shorter than 1.8 s were not investigated for this

load inductance or module charge voltage, however based on

earlier test shots the peak load current is likely to begin dropping

more rapidly as the crowbar trigger delay is reduced below

1.8 s. Thus, 1.8 s appears to be the optimum delay time for

triggering the crowbar switch. A possible method for reducing

the hardware-related inductance and therefore the amplitude of

the oscillations in the load current waveform is discussed in the

next section.

IV. POSSIBLEMODIFICATIONS TO LOWER SWITCH INDUCTANCE

Other design arrangements for the crowbar switch exist that

would allow for lower crowbar inductance, designs in which the

crowbar rail gaps are mounted between two parallel bus plates

in the same way that the main discharge gaps are mounted on

the front of the Shiva Star modules. In these schemes, the rail

gaps are located two on each side of the module or on an extension

to the bus plates that would place the four rail gaps beside

the main discharge gaps. The present design was chosen,

however, because it required very little additional hardware to

the cable header, and no changes to the existing Shiva module

hardware (bus plates) were needed. Analysis and experiments

may show that the field-reversed configuration is stable enough

such that the oscillations in the crowbarred reverse discharge

current (reverse magnetic field) will not significantly affect its

formation and lifetime. However, if the current oscillations are

found to have an adverse affect on the FRC, examination of the

present crowbar switch design shows that there are some relatively

minor changes can be made to reduce the crowbar switch

inductance and thereby reduce the amplitude of the current oscillations.

A cross-sectional diagram of the crowbar switch configuration

with the proposed changes indicated is presented in

Fig. 15. At present the crowbar rail gaps are approximately

9/16 in. above the bottom edge of the support brackets holding

them; if the rail gaps are moved down until their bottom edge

is even with the support brackets, and if both the lower face

of the support brackets and the rail gaps are moved down by

an additional 0.5 in., as shown in the figure, then calculations

show that the inductance of the crowbar switch can be reduced

by approximately 4.47 nH.

To determine what kind of effect reducing the switch inductance

by this amount would have on the load current waveform,

some simulations of the crowbar test circuit were performed

again using Micro-Cap. Fig. 16 shows the first 18 19 s of

the load current waveform from Test Shot 37 along with the

calculated load current waveform provided by Micro-Cap. Assuming

a switch inductance of 10.1 nH, fairly good agreement

is obtained between the Micro-Cap calculation and the experimental

result, at least until s. When the total

crowbar switch inductance is reduced by 4.47 nH, the third trace

in Fig. 16 is obtained. This trace has a slightly lower peak current,

1.18 MA, however the value of the current at the first

minimum has risen to 800 kA, resulting in a ratio of 0.68.

(Recall that for Test Shot 37 is 0.579.) As indicated in Fig. 15,

the only hardware components that would need to be modified

in order to obtain this improvement are the angle brackets supporting

the crowbar rail gaps above the cable header. Thus, this

improvement could be made at relatively little cost and down

time.

V. SUMMARY AND EVALUATION OF PERFORMANCE

The crowbar tests were performed with charge voltages of

up to 80 kV on the Shiva capacitor bank module, during which

currents of up to 1.25 MA were crowbarred. No evidence of

flashover in the crowbar or load cable headers was observed

when the headers were adequately filled with SF . In order to

achieve the desired load current (theta coil current) of 1.5 MA,

however, the charge voltage will have to be increased to slightly

higher values of 100 kV. As long as an adequate filling of

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.