-----(In compliance with GOST 23279 – 85)-----

*****************************************************************

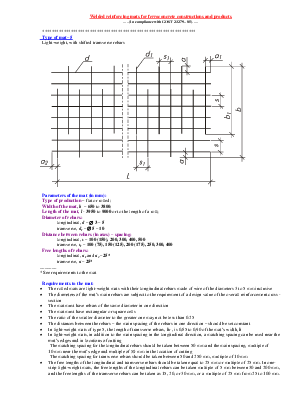

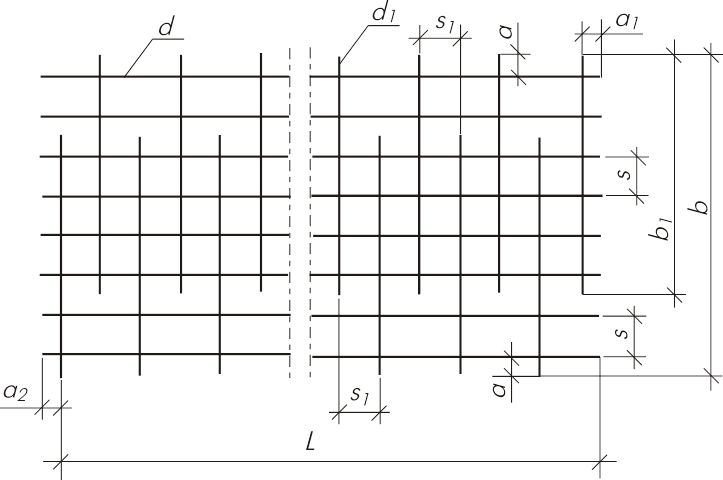

Type of mat– 5

Light-weight, with shifted transverse rebars

Parameters of the mat (in mm):

Type of production– flat or rolled;

Width of the mat, b – 650 to 3800;

Length of the mat, l - 3950 to 9000 or to the length of a roll;

Diameter of rebars:

longitudinal, d – Æ 3 – 5

transverse, d1 – Æ 5 – 10

Distance between rebars (in axes) – spacing:

longitudinal, s – 100 (150), 200, 300, 400, 500

transverse, s1 – 100 (75), 150 (125), 200 (175), 250, 300, 400

Free lengths of rebars:

longitudinal, a1 and a2 –25*

transverse, a – 25*

_______

* See requirements to the mat

Requirements to the mat:

· The rolled mats are light-weight mats with their longitudinal rebars made of wire of the diameters 3 to 5 mm inclusive

· The diameters of the mat’s main rebars are subject to the requirement of a design value of the overall reinforcement cross-section

· The mat must have rebars of the same diameter in one direction

· The mat must have rectangular or square cells

· The ratio of the smaller diameter to the greater one may not be less than 0.25

· The distances between the rebars – the main spacing of the rebars in one direction – should be set constant

· In light-weight mats of type 5, the length of transverse rebars, b1 , is 0,85 to 0,90 of the mat’s width, b

· In light-weight mats, in addition to the main spacing in the longitudinal direction, a matching spacing can be used near the mat’s edges and in locations of cutting

The matching spacing for the longitudinal rebars should be taken between 50 mm and the main spacing, multiple of 10 mm near the mat’s edge and multiple of 50 mm in the location of cutting

The matching spacing for transverse rebars should be taken between 50 and 250 mm, multiple of 10 mm

· The free lengths of the longitudinal and transverse rebars should be taken equal to 25 mm or multiple of 25 mm. In one-strip light-weight mats, the free lengths of the longitudinal rebars can be taken multiple of 5 mm between 30 and 200 mm, and the free lengths of the transverse rebars can be taken as 15, 20, or 30 mm, or a multiple of 25 mm from 25 to 100 mm.

· The spacing between the longitudinal and transverse rebars of light-weight mats indicated in parentheses can be used in feasibility studies.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.