|

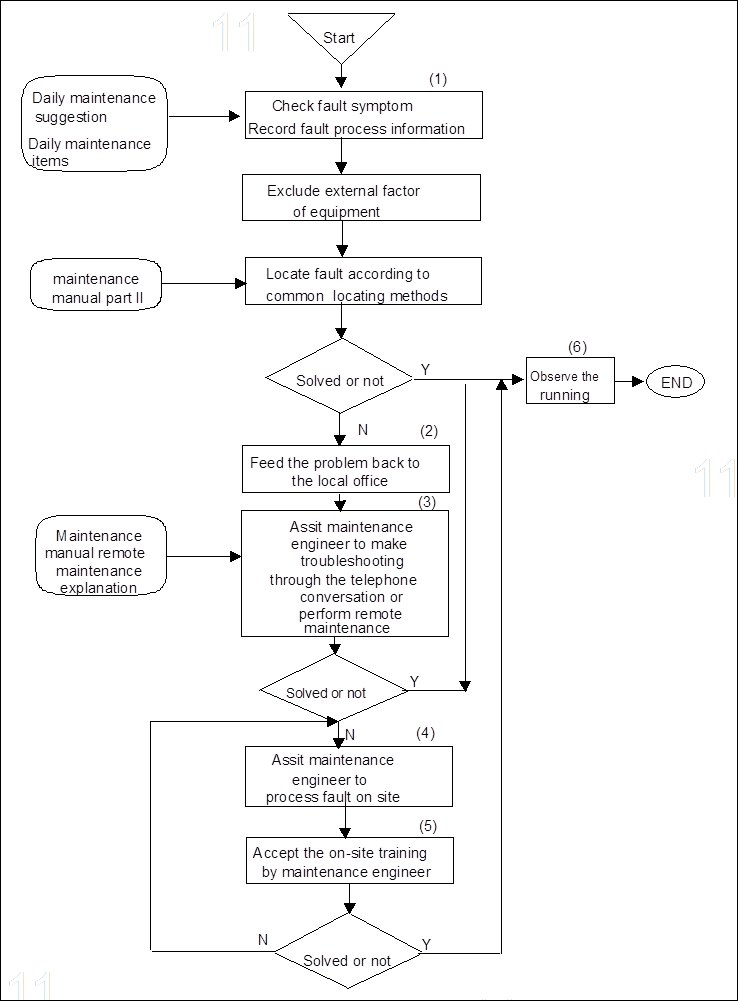

3.1 Serious Fault Processing Flow Chart

1. Flow Chart

The serious fault during the operation of OptiX transmission equipment refers to the fault of user service interruption caused by such reasons as power failure, fiber broken, improper maintenance operation and instability of the equipment, which also requires quick and accurate localization and processing during maintenance operation. Therefore, the serious fault processing flow chart as illustrated in Figure 3-1 is summarized so as to make a standardized flow guide for the staggered troubleshooting procedures taken by maintenance personnel in the equipment room as well.

2. Precautions

When the serious fault is processed according to this flow, the following points should be paid much attention to:

(1) On the principle of resuming service as soon as possible, be sure to make fault records simultaneously for analyzing, so as to avoid the missing of potential problems.

(2) During troubleshooting, perform such dangerous operations as power failure, unplugging board and unplugging fiber, etc. as less as possible to prevent the problems from being enlarged due to improper maintenance operation.

(3) Make every effort to solve problems by analyzing the fault and do not replace board blindly.

(4) In case the problems can not be solved by yourself, please contact the local office of Huawei Technologies Co., Ltd. for technical support if the condition permits, and coordinate with the maintenance engineer in Huawei Company to locate the fault with employment of remote maintenance mode, so as to reduce the service-interrupted time to the utmost.

(5) Implement the maintenance system that special persons are in charge of NM and equipment, accomplish software and hardware maintenance level management as well as personnel training.

(6) Equipment maintenance personnel should pay attention to study maintenance knowledge and learn maintenance experience from the troubleshooting process.

(7) The detailed records for fault description and troubleshooting process should be made and feed back to the local office of Huawei Technologies Co., Ltd. in time.

Figure 3-1 Serious fault processing flow

3.2 Operation Guide

The procedures marked with serial numbers in Figure 3-1 should be completed according to the following operation guides.

(1) In case there is a serious fault affecting service, first check the data such as alarm, performance, etc. in NM before solving the problem, and record these data and on-site fault description.

Then locate the fault according to the common fault locating methods introduced, exclude external factors and the faults occurring frequently during equipment running.

(2) If it is difficult to locate the fault, please feed back the records of fault description and troubleshooting process at earlier stage as well as the written information such as alarm and performance report, etc. to the local office of Huawei Company.

(3) Assist maintenance engineer to make telephone investigation, analyze, check and process the fault as the instruction of maintenance engineer. If the fault can not be located only by telephone instruction, please coordinate with maintenance engineer to perform remote maintenance operation to make remote localization.

(4) If the problems can not be solved by the above measures, maintenance engineer in Huawei Company will go to the site to perform operations. In this case, please assist the maintenance engineer to make on-site investigation, introduce the equipment running conditions before and after the fault as well as troubleshooting process in details, and provide alarm and performance information record or report. Assist maintenance engineer to go to the station which might have problem to make on-site examination, provide the required condition to resume service quickly.

(5) In the course of assisting to make troubleshooting, accept the on-site training by maintenance engineer, grasp the methods for processing the faults of the same category and record the operating procedures and corresponding faults.

(6) After the problem is solved, fill in “OptiX BWS 320G Daily Abrupt Problems Treatment Record Sheet”, observe and record the running conditions of equipment and make sure the problem is solved absolutely.

Serious Fault Processing Flow...................................................................................................................................... 1

3.1 Serious Fault Processing Flow Chart................................................................................................................. 1

3.2 Operation Guide............................................................................................................................................. 4

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.