|

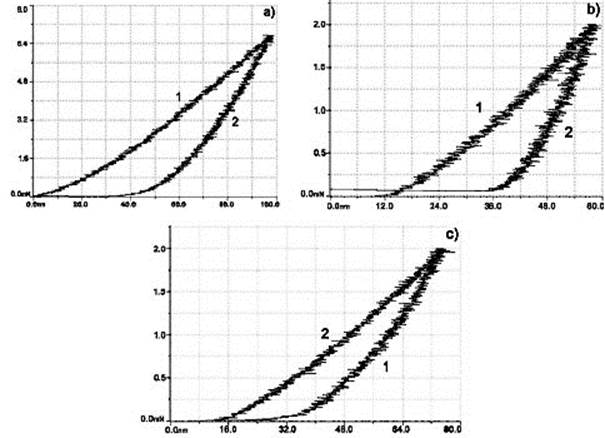

In Figure 3, the loading and unloading

curves are shown for some Ti/Si and C/Si coatings. Comparing the plots 3a

and 3b, one can see that with increasing target-substrate distance, the

coating plasticity increases. It should be noted here that its nanohardness

increases as well, and rather substantially.

For the C/Si film, the scratch microphotographs at different

indentation loads are shown in Figure 4. Here, d=90 mm, and the

carbon film thickness t=0.11 mm. In spite of the

small film thickness, it flakes away from the substrate even at the minimal

indentation load of 0.01 N. It is seen from Figure 2 that for the Ti/Si

film of the same thickness, Fcr»0.35 N. Thus, the

adhesion of Ti/Si coating is much better than that of C/Si. The reason for

that is in big internal tensions in deposited carbon films often resulting

in their spontaneous cracking as is seen in Figure 4c. Also, the presence

of big tensions is confirmed by the atypical unloading curve for the C/Si

coating, which is placed to the left of the loading curve (see Figure 3c).

Earlier, we observed significant cracking of carbon films deposited on

glass at the target-substrate distance of 50 mm.

FIGURE 3. Loading (1)

and unloading (2) curves for: a) Ti/Si coating, t=0.23 mm, d=55 mm; b) Ti/Si coating, t=0.07

mm, d=90 mm; c) C/Si coating, t=0.11

mm, d=55 mm. Maximum normal force

FN=2 mN

FIGURE 3. Loading (1)

and unloading (2) curves for: a) Ti/Si coating, t=0.23 mm, d=55 mm; b) Ti/Si coating, t=0.07

mm, d=90 mm; c) C/Si coating, t=0.11

mm, d=55 mm. Maximum normal force

FN=2 mN

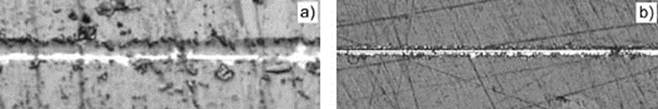

In Figure 5, the scratch microphotographs of Ti/Fe (t=0.08

mm) and C/Fe (t=0.13 mm) films are shown. In

spite of the Ti coating is ~1.5 times thinner than C coating, its adhesion

is evidently worse. Meanwhile, the difference in the linear expansion

coefficients of titanium and iron (8.3×10–6 and 12×10–6

K–1, respectively) is smaller than such difference for carbon

and iron (26.7×10–6 and 12×10–6 K–1), so that

internal tensions in the carbon film is higher. Obviously, in this case,

the main factor determining the adhesion of C/Fe coating is the formation

of strong chemical bond Fe-C between the film and substrate.

Comparing the adhesion of the Ti/Fe coating (Fcr=0.01

N at t=0.08 mm) and Ti/Si coating (Fcr=0.35 N at t=0.11

mm), one can see significantly better adhesion of the Ti/Si

coating. This is also connected with the formation of strong chemical bonds

in the film-substrate system due to the substrate heating by ablation

plasma. Since the compounds of titanium and silicon Ti5Si3,

TiSi, TiSi2 are formed at lower temperature (860° C) than the

compounds of titanium and iron TiFe, Ti3Fe3O

(1317 °C) [5], the probability of the formation of Ti-Si bonds is

higher.

CONCLUSION

The investigations performed have shown that the adhesion

strength of thin-film coatings substantially reduces as their thickness

increases and target-substrate distance decreases. At all other conditions

fixed, the adhesion of Ti/Si coatings is better than that of C/Si coatings

that is explained by big internal tensions in carbon films. At the same

time, the adhesion of Ti/Fe coatings is worse than that of C/Fe coatings

that can be explained by the formation of strong chemical bonds Fe-C in the

transition region between the coating and substrate.

FIGURE 4. Scratch

microphotographs of C/Si film: a) FN=0.09 N; b) FN=0.43

N, t=0.111 mm, d=90

mm

FIGURE 4. Scratch

microphotographs of C/Si film: a) FN=0.09 N; b) FN=0.43

N, t=0.111 mm, d=90

mm

FIGURE 5. Scratch

microphotographs of Ti/Fe coating: a) FN =0.02 N, t=0.082

mm; b) FN =0.02

N, t=0.127 mm, d=90

mm

FIGURE 5. Scratch

microphotographs of Ti/Fe coating: a) FN =0.02 N, t=0.082

mm; b) FN =0.02

N, t=0.127 mm, d=90

mm

REFERENCES

1. Ivanov Yu. F., Matvienko V. M., Potyomkin A.

V., Remnev G. E., Zakutaev A. N., in Ion Solid Interactions for Materials

Modification, Processing, edited by D. B. Poker, D. Ila, Y. -S. Cheng, L.

R. Harriott, T. W. Sigman, Mater. Res. Soc. Proc., 396, Pittsburg PA , 1996, 593–598.

2. Renk T. J., Provencio P. P., Prasad S. V. et

al. Materials Modification using Intense Ion Beams // Proceedings of

the IEEE, 92, 1057–1081, 2004.

3. Xianghui Wang, Xianghuai Liu, Xi Wang et

al., Surf., Coat. Techn.

158-159, 563–567, 2002.

4. Baglin J. E. E., Nucl. Instrum., Meth. Phys.

Res. B 65, 119–128, 1992.

5. Kornilov I. N., Budberg P. B. State Diagram of Double, Triple Titanium Systems. M.: VINITI, 1961 (in Russian).

|