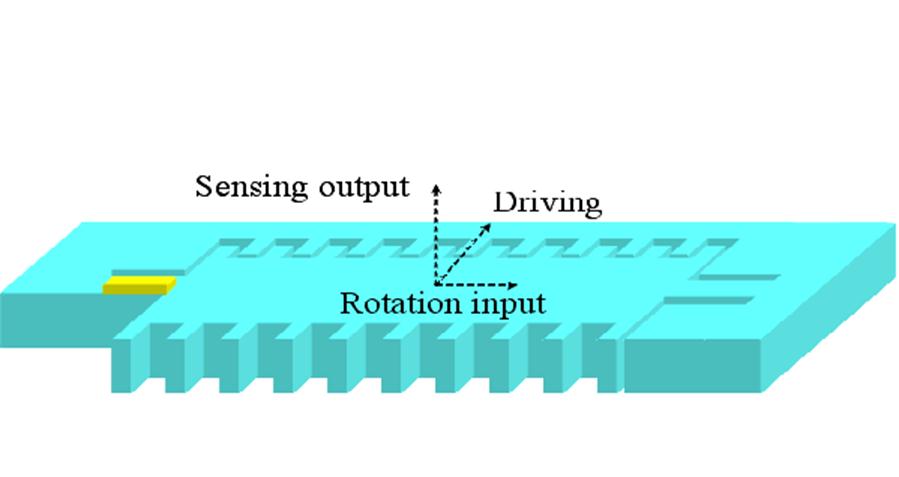

Пъезорезистивный микрогироскоп

Принцип работы

Технологический процесс изготовления:

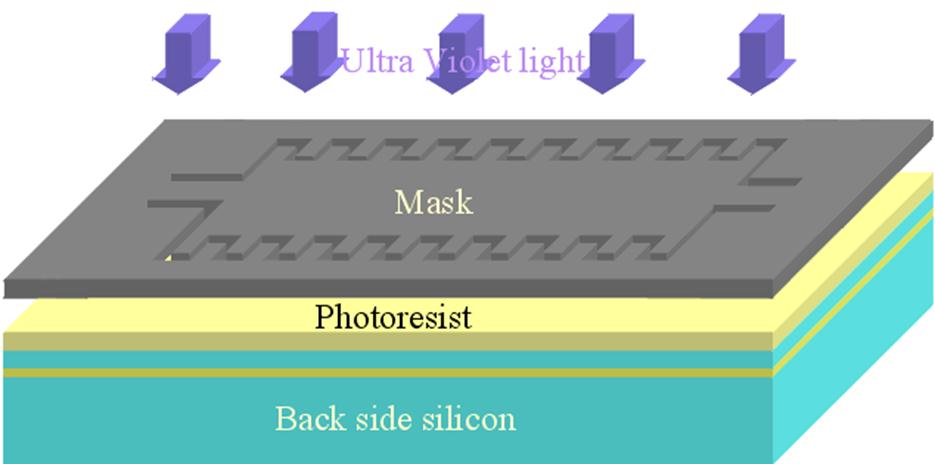

Front side photolithography. The shape of the comb-drive is pre-printed in a mask (a glass plate where the printed regions are transparent, while others are opaque). When ultra-violet(UV) light is shined through the mask, light goes through the transparent regions and hit the photoresist, a special material which is sensitive to UV light. Then the exposed photoresist is rinsed away and the pattern in the mask (i.e. the comb-drive) is transferred to the photoresist layer. Believe it or not, this process is pretty much how you take photos and have them printed!

1.

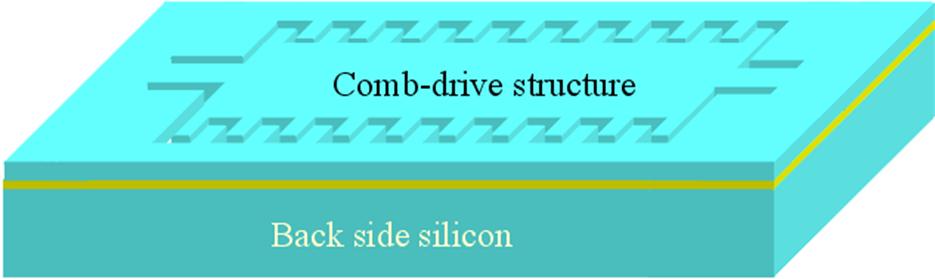

The patterned photoresist is used as DRIE (Deep Reactive Ion Etching) mask, so the pattern is transferred to the top silicon layer after etching.

2.

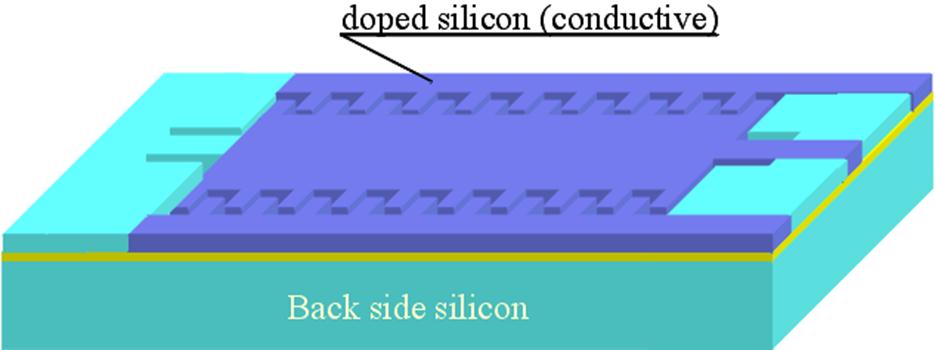

Certain regions in the top silicon layer are doped (a standard process where impurities are added to silicon to increase the electrical conductivity) to form electrodes.

3.

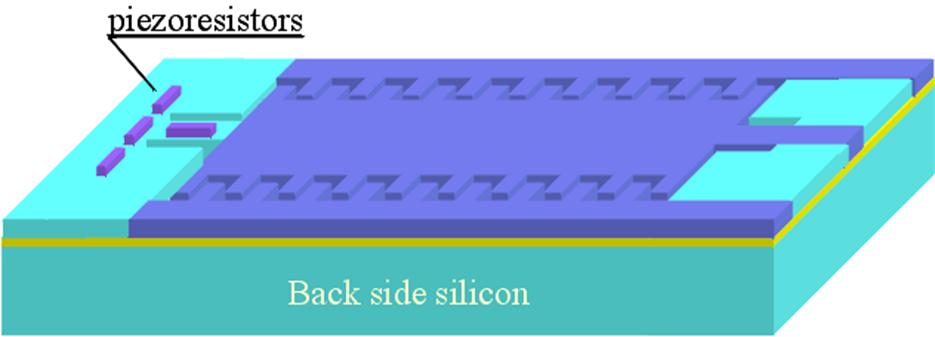

Piezoresistors are implanted (another process in which impurities can be added. But doping level can be accurately controlled in ion implantation). The one on the bridge is the sensing element, while other three serve as a Wheatstone bridge as well as temperature compensation elements.

4.

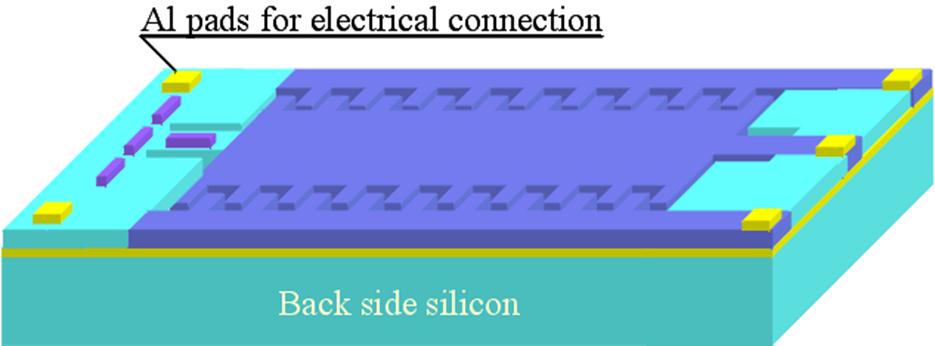

Aluminum pads are deposited to make electric connections.

5.

The comb-drive structure is release from the back side by DRIE etching.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.