· Detection Method: the detection method describes how the operator or the maintenance technician detects a specific failure. Warning devices, test equipment, and their normal or abnormal indication are described by the detection methods.

The basic objective of the task analysis is to define necessary tasks for the support and operation of the product. Reliability Centered Maintenance techniques can be used to decide what needs to be done to either correct a failure or to prevent a failure from occurring.[18]

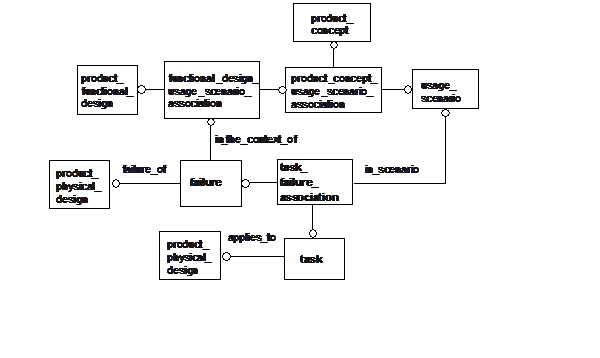

A task applies to one or more product_physical_design instances. These are not necessarily the same product_physical_design instances identified in the failure analysis[19].

A task is performed in a support_scenario that describes under which conditions (environment, national regulations, available skills, etc) the task is expected to be performed.

|

Figure 10 - task basic relationships

A task provides the instructions on how to perform a particular activity or action.

Some information requirements related to task are the followings:

30. task(s) may be classified. Servicing Tasks, Scheduled Tasks, Occasional Tasks are examples of task classes;

31. a task may relate to another task for a particular reason;

32. the possible rationale for two task(s) to be related should be defined. Alternate task(s) is an example of this rationale;

33. maintenance level[20], criticality, and other qualifications may be assigned to a task;

34. some task characteristics such as time to perform and cost may be derived by the roll-up of sub-task attributes;

35. when and whether to perform a task depends on conditions. A simple condition may define, for example, that a task is to be performed every three months (e.g. do task ‘A’ IF date(current)-date(task_A_last_done)>90)[21];

36. simple conditions may be combined with AND, OR and XOR logical operators to define more complex conditions (e.g. do task ‘A’ IF date(current)-date(task_A_last_done)>90 .OR. mileage(current) – mileage(task_A_last_done) > 3000 );

37. condition monitoring may require that certain parameters of product_instance and support_scenario be measured and recorded. Where data is collected automatically the source sensor[22] should be identified.

A task is usually decomposed in elementary task stages or steps that may be seen as modular building blocks. Tasks may be defined by assembling the elementary (base) stages using selected criteria.

Some requirements for base_stage are the followings:

38. a base_stage may be assigned to zero, one or many task(s). This implies that a base_stage may exist without a task[23] and that the same base_stage may be assigned to many task(s);

39. a base_stage may be either a method_stage (what to do) or an advisory_stage (warnings, cautions, … );

40. a task shall include at least one method_stage;

41. a method_stage may be described in different forms, e.g. by a simple narrative description of what to do or by more sophisticated forms of representations such as video, audio, virtual reality;

42. some resources[24] may be needed to perform the activity described by a method_stage. Resources may have a role[25] (e.g. spare parts, consumables, test equipment, calibration equipment, etc.) and may be quantified;

43. the identified resources include the following:

· facility_or_infrastructure: this may be a reference to a generic facility (e.g. 220V power supply) or a generic infrastructure (e.g. a dry-dock). It also may be a reference to a specific named and located facility;

· information_requirement: a reference to the applicable information (drawings, wiring diagram, manuals);

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.