D = effective mill diameter (inside shell liners), m

L = effective grinding length (EGL) expressed as the length along the mill cylinder at the mill shell in between the feed end liner plate and the inboard side of the discharge grate plate, m

PN = Power number calculated from mill power measurements and which takes into account mill speed and all aspects of the charge motion within the mill cylinder and both conical ends: impact breakage, attrition, abrasion, friction and rotation within the mill charge, losses due to heat and sound emanating from within the mill, wind loss, shape of the mill charge, the imprecise position of the centre of gravity of the mill charge, size analysis of the mill charge, and no-load power.

and ρc =

(7)

(7)

% v/v = volumetric percentage of the total mill volume

Where ρ = specific gravity

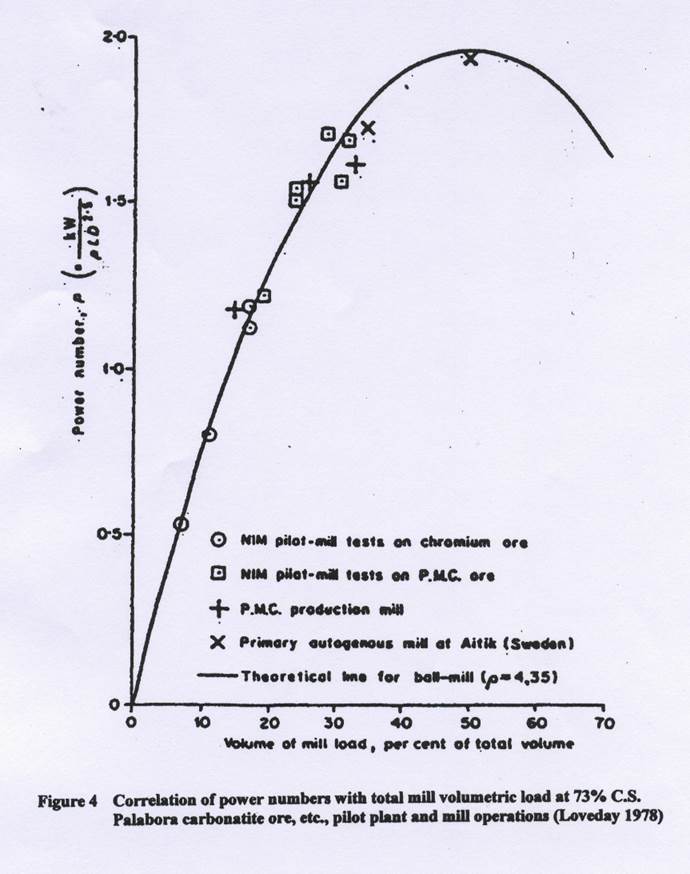

Values of PN are shown in Figure 4 from Loveday's work in which he established a good correlation for power numbers calculated from carefully run pilot plant testwork on Palabora carbonatite ore and surveys at mill operations while varying the volumetric filling of the autogenous mill load.

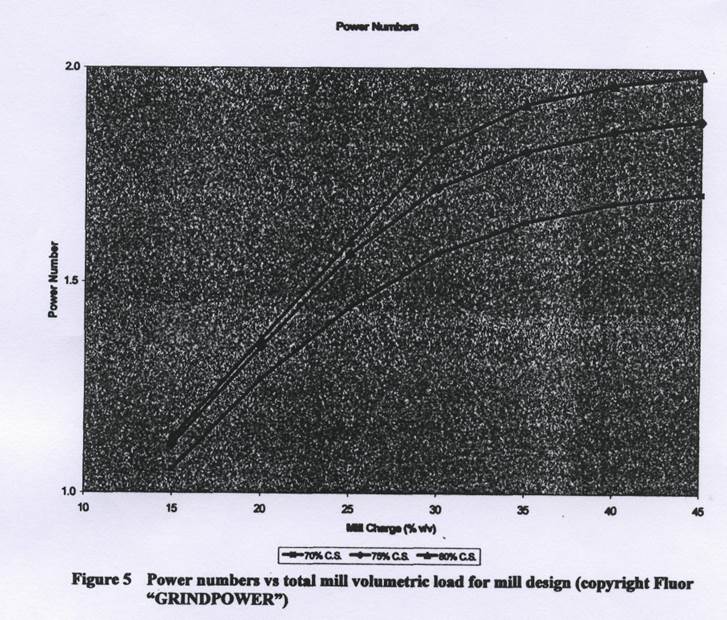

In Figure S, the author1 has utilized this principle of power number, beginning with plant surveys in 1986, to generate a family of curves, similar in profile to Loveday's in Figure 4, for different mill speeds and the same range of total mill volumetric filling. Figure S illustrates power number curves for conical-ended mills and three selected mill speeds. Power numbers for flat-ended mills are usually up to 5% lower.

Whereas this data is proprietary to Fluor as an integral part of the "GRINDPOWER" mill sizing program (Matthews and Barrett 1991), it has continued to benefit from surveys with variable speed mills, particularly with gearless drives, over the last 15 years. Once the net grinding power requirement is set, "GRINDPOWER" requires input regarding:

· Type of drive; single pinion, dual pinion, or gearless

· The desired number of mills to process the required throughput

· Anticipated ball charge volume, % v/v

· Total mill volumetric filling, % v/v

· Mill % critical speed

· Mill pulp density, % solids w/w.

The program calculates a trial mill diameter based on an assigned power number (it automatically "looks up" the required power number) and a O:L ratio of 3:1 in the case of a high aspect mill. This trial diameter is adjusted to the closest standard nominal diameter, then the program re-calculates the effective grinding length (EGL). A standard mill EGL is entered and minor adjustments are made to the operating conditions; e.g., mill speed, so that the calculated mill EGL is in agreement with the selected standard EGL. The process can be repeated for other operating conditions and the required net mill power draw is checked to ensure that it is higher than the power required for grinding. In order to set the motor power, the engineer is prompted to input the maximum anticipated ball charge, and if necessary to re-iterate at a higher mill speed (in anticipation of the next stage of mill sizing investigation: the "tent" diagram). Motor power is then calculated and a standard motor horsepower is selected. This method can be used to size both high and low aspect autogenous and semi-autogenous mills, and pebble mills.

It is important to note that power numbers can be calculated for any AG/SAG grinding operation based on the results of a detailed internal survey of a mill following a controlled "crash" stop.

SAG mills that have been sized using the power number and "GRINDPOWER" approach include: Cadia Hill (study), Batu Hijau, Alumbrera, Collahuasi, El Teniente, Ernest Henry, Boddington (studies), La Candelaria, Fimiston, INCO Clarabelle, Freeport 9SK Expansion, Lisheen, and Dreifontein. In-plant checks on mill performance have been made, largely in connection with optimization of shell liner/lifter design, mill speed, and ball volumetric loading, for Los Pelambres, Batu Hijau, Alumbrera, Troilus, and Lac Des lies, as well as numerous studies and plant audits. Power numbers so used are believed to be accurate to within 2% to 3%.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.