The above is just a simple and illustrative example of how a single metric that combines both the knowledge of strategic importance and of trade-off – compatibility relationships between each pair of strategic competitive priorities can be obtained. It can be easily extended to include more areas of manufacturing performance (e.g. innovation, flexibility), and also a broader scale of assessment (e.g. a scale of 1-5 points instead of 1-3). This new approach observes similarities with other methodologies that aim at reconciling differences of opinion and awareness of potential operational interconnections (e.g. FMECA, QFD). It can potentially determine the knowledge that an employee has regarding the strategic importance of the different areas of manufacturing performance. More importantly, however, is that this methodology can assess the employee's real knowledge of the potential trade-off – compatibility relationships between each pair of manufacturing competitive priorities. This new approach and methodology improves on previous studies on at least two levels:

1. It incorporates mainstream and well-grounded theory in operations management into the study of strategic consensus and its effect on performance. Since the need for more theory-driven research in the operations management field has been emphasised (Handfield, 2002), the relevance of this new approach and methodology becomes more important. As was noted in preceding sections, previous methodologies and approaches used in a number of studies fall short and do not consider the trade-off – compatibility research that has been proposed and advanced over the past four decades in the manufacturing strategy/operations management field (Skinner, 1969, 1974; Ferdows and de Meyer, 1990; Noble, 1995; Collins et al., 1998, Safizadeh et al., 2000).

2. Previous methodologies and approaches to the study of strategic consensus and its impact on manufacturing performance rely on at least two respondents for every company surveyed in order to measure their consensus and agreements regarding the strategic importance of each competitive priority. Our methodology can be used with multiple respondents from several levels within a firm or with only a single respondent. While we acknowledge that having multiple respondents is advantageous in several ways (e.g. accuracy and reliability of a construct), it can also be problematic to obtain responses from several individuals in an organisation, especially if the study is mail survey-based. With our approach, it is possible to obtain the ERKTO score with only one respondent from each organisation surveyed. A single respondent can potentially answer questions about the importance of performance areas such as quality, delivery, etc. This same respondent could also answer questions regarding the potential trade-offs relationships between each pair of competitive priorities. Having a single respondent for each company could generate a better response rate. We realise that it is difficult to assume that a single respondent adequately represents an entire organisation. Nonetheless, this assumption is consistent with previous studies that have confirmed various theoretical concepts in operations management using a survey-based approach with single respondents from each participant firm (Shah and Ward, 2003; Nahm et al., 2003).

This paper has examined the issue of strategic consensus on manufacturing competitive priorities and performance. While the topic of strategic consensus has been the focus of much research in the business strategy field, it is evident that this theme has been under-researched in the field of operations management. The few research papers found in the literature review represent a first and necessary step. To take a critical approach and identify research gaps this early into the development of this topic offer interesting and challenging opportunities. The following are some of the important themes that we think need to be explored in future studies:

As noted by Handfield (2002), it is necessary for operations management research to be more driven by theory. This type of research will in turn advance the theory-building process in the field. Our paper has taken a critical approach to studies that have examined strategic consensus on manufacturing competitive priorities, and how it can affect organisational performance. It is evident that this theme has been under-researched. Several inadequacies have been found, and potential solutions have been proposed. We believe that future research can benefit from these proposals, and that these will contribute to the development of this emerging topic. And as commented before, the new methodology has the potential to be a practical tool that can aid managers in having a more capable and knowledgeable workforce inside their organisations.

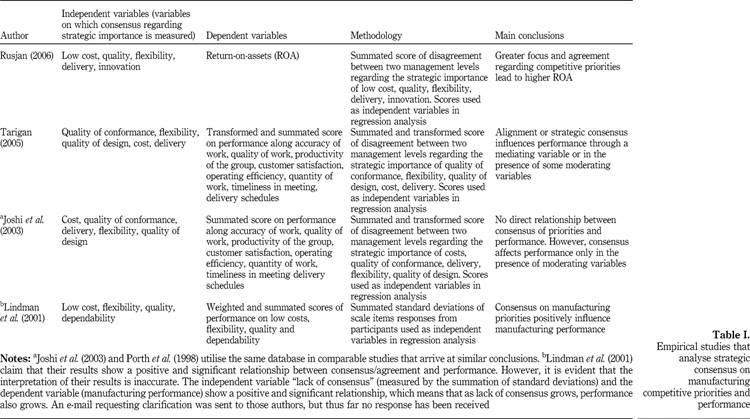

Table IEmpirical studies that analyse strategic

consensus on manufacturing competitive priorities and performance

Table IEmpirical studies that analyse strategic

consensus on manufacturing competitive priorities and performance

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.