Nucleation Rate Surfaces for Modeling of Nanomaterial Generation from Crystals under Short Pulses of Energy

Michael P. Anisimov, Anatoly M. Baklanov, and Artyom V. Trilis

Institute of Chemical Kinetics&Combustion SB RAS, 3 Institutskaja Street, 630090 Novosibirsk, Russia.

ABSTRACT

The nucleation rate surface using is a new promissing tool for computer modeling of nanomaterial generation from crystals under short pulses of energy. A nucleation rate surface design over a diagram of phase equilibria is used for geometrical presenting of nanosize particle generation under short pulses of energy. Nanoaerosol which is appeared from melted wire under powerful electric pulse or laser ablation, milling of crystals, etc can be mentioned as examples. Particle generation kinetics are investigated experimentally and theoretically. Nevertheless one might say that nucleation rate surface topologies for the gas and liquid embryo generation kinetics are not fully understood up to now. The nucleation rate surface topologies for metastable crystal relaxation kinetics are considered in the present research.

1. Introduction

Computer modeling of the nanosize particles generation kinetics can be realized using any parametric model. These kinds of models can be applied for the frames of the parameterization areas as a rule. A model using beyond the parameterization intervals can be successful in the case of physically true parameterization only. Using the nucleation rate surface topologies gives chance to raise the modeling reliability. There are a lot of the experimental and theoretical investigations of melting and boiling kinetics in application to solid (crystalline or glassy) materials with evaporation and aerosol formation following then. As examples can be mentioned the conducted wires which can blow up under electrical current [1], the laser ablation of crystals [2], etc. Nevertheless the nucleation rate surface topologies for the gas and liquid embryo production from metastable crystals are do not enough understood up-to now. Case of topologies for metastable crystal relaxation kinetics is considered in the present research.

2. Nucleation Rate Surface Semiempirical Design. Results and Discussion

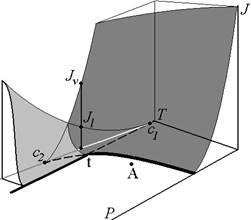

The nucleation rate surface topology for embryo-forming under the laser ablation is considered on the base of simplified PT phase diagram with triple point shown in Fig. 1, following article [3]. Where P is total pressure, T is temperature, and J is nucleation rate. The nucleation rate surfaces for droplet and vapor embryos are shown schematically. Surfaces overlap each other in interval between metastable critical points which are signed by с1 and c2. Several assumptions are used to design of the nucleation rate surfaces, i.e. nucleation rate along the phase equilibrium

Fig. 1. Topology of nucleation rate surfaces over PT phase diagram for droplet formation (gray) and vapor embryo formation (dark gray) from crystal or glass. Point, t, is triple one.

lines has zero values. The maximum nucleation rates are achieved at the spinodal conditions. It is assumed that nucleation rate surface is represented by continuous and monotonous function for one given phase state. Nucleation rate at the critical points has zero value because these points are representing the second order phase transitions where two different phase coexistence is impossible.

The initial state of crystal is marked schematically by letter A. In case of a crystal-vapor or crystal-liquid equilibria the initial state point is located on the appropriate line of phase equilibria. A laser pulse produces temperature and pressure growth at the spotlight crystal layer. Crystal under fast heating may reach the spinodal conditions where droplets and vapor embryos have barrierless nucleation. The droplet nucleation rate is associated with surface which arises from line for crystal melting. The spinodal droplet nucleation rate, Jl, in Fig. 1 is shown at condition governing by the total energy of laser beam pulse. Nucleation rate, Jv, is associated with the vapor embryo generation at the crystal-vapor spinodal condition.

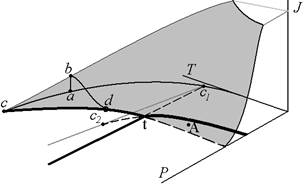

Fig. 2. The simplified PT phase diagram following article by Anisimov et al. [3].

One can find in Fig. 1 that the vapor embryos generation can be detected only at low enough pressure within a spot of laser beam pulses. Droplets generation can be found in addition to vapor generation at more powerful laser radiation and lower total pressure. Energy growth for laser beam pulses result pressure growth as well as the relative droplet contains following the nucleation rate surface topology for liquid embryos. Sublimation mechanism disappears at some high enough density of laser pulse energy. I.e. the vapor generation becomes the ability to be produced in that case in the result of droplet evaporation only. The schematic topology for the vapor nucleation rates in liquid (or droplets) is presented in Fig. 2. Droplets can reach the spinodal conditions for liquid when laser pulse energy is enough. That case is discussed in review [1]. The vapor nucleation rate gets the maximum value at the spinodal conditions, when the laser pulse radiation become over then vapor gets supercooled and generates droplets, nanocrystals and nanoglasses. For example, Buckle at al. [4] gets the amorphous and crystal particles from Zn vapors. Non-evaporated droplets should grow under the vapor cooling then freeze to the crystal or glassy particles. Seemingly the nucleation surface topology for glasses should continue a surface for droplet nucleation which is shown in Fig. 3.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.