|

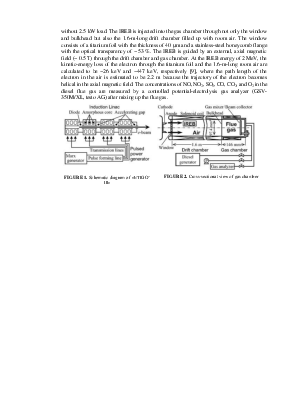

Diesel Flue Gas Treatment by Intense, Pulsed Relativistic Electron Beam Go Imada*, Tomoki Sakurai, and Kiyoshi Yatsui Extreme Energy-Density Research Institute, Nagaoka University of Technology 1603–1 Kamitomioka, Nagaoka, Niigata 940-2188, JAPAN Abstract. Diesel-flue-gas treatment has been demonstrated by using an intense, pulsed relativistic electron beam (IREB). A flue gas treatment chamber, 1.6-m isolated from the IREB source, is filled up with the diesel flue gas with the pressure of 200 kPa, and is irradiated by IREB (2 MV, 0.12 kA, 65 ns (FWHM)). The maximum kinetic energy of IREB injected into the gas chamber is experimentally estimated to be ~0.23 MeV. When the diesel flue gas is irradiated by firing 10 shots of the IREB, the concentration of NOx, SO2, and CO are decreased from 75, 14, and 770 ppm to 5, 11, and 690 ppm, respectively. It is found that ~ 93 % of NOx is removed by firing 10 shots of the IREB irradiation. We have obtained the energy efficiency of NOx removal of 256 g/kWh. INtroduction Nitrogen oxide (NOx) and sulfur dioxide (SO2) have induced environmental problem in the earth such as deforestation. To reduce the NOx and SO2 in atmosphere, flue gas treatment by electron beam has been attracting attention [1–5]. Intense, pulsed relativistic electron beam (IREB), in particular, is a promising candidate for the electron beam source of the flue gas treatment due to its particular characteristics such as high current density and long range. In our previous research, dry-N2/O2-balanced NOX gas mixture filled in a long chamber and a chamber spatially isolated from electron beam source have been successfully treated by the IREB irradiation [6, 7]. In this study, the diesel-flue-gas treatment by the IREB has been demonstrated by using a pulsed power generator, «ETIGO–III». The diesel flue gas which contains NOx, SO2, H2O, CO2, and so on is generated by a diesel generator, and is irradiated by the IREB having the kinetic energy of order of MeV. The kinetic energy of electron injected into the gas treatment chamber has been observed by measuring the IREB current passed though the various sets of thin metallic foil with energy loss. Experimental set-up Figure 1 shows the schematic diagram of pulsed-power generator, «ETIGO-III» [8]. The output voltage of the pulse forming line is ~670 kV, which is fed to the acceleration cells through the transmission lines in parallel. Three amorphous-metallic cores are installed in each cell, producing approximately 2 MV per cell (670 kV × 3). The electron beam with the energy up to 2 MeV is generated by an electron-beam diode set at the first acceleration cell. The field-emission foilless diode with a hollow cathode is used to generate the electron beam. Figure 2 shows the cross-sectional view of flue gas treatment chamber. The gas chamber is made of a stainless-steel pipe with the volume of ~1.1 ℓ. After the gas chamber is evacuated to ~20 Pa by a rotary vacuum pump, it is filled up with a diesel flue gas with the pressure of 200 kPa which is supplied from a diesel generator (KDG3500E-BL, Komatsu Ltd.) with and without 2.5 kW load. The IREB is injected into the gas chamber through not only the window and bulkhead but also the 1.6-m-long drift chamber filled up with room air. The window consists of a titanium foil with the thickness of 40 mm and a stainless-steel honeycomb flange with the optical transparency of ~ 53 %. The IREB is guided by an external, axial magnetic field (~ 0.5 T) through the drift chamber and gas chamber. At the IREB energy of 2 MeV, the kinetic-energy loss of the electron through the titanium foil and the 1.6-m-long room air are calculated to be ~26 keV and ~447 keV, respectively [9], where the path length of the electron in the air is estimated to be 2.2 m because the trajectory of the electron becomes helical in the axial magnetic field. The concentrations of NO, NO2, SO2, CO, CO2, and O2 in the diesel flue gas are measured by a controlled potential-electrolysis gas analyzer (GSV-350M/XL, testo AG) after mixing up the flue gas. |

|

|

|

|

Figure 1. Schematic diagram of «ETIGO-III» |

Figure 2. Cross-sectional view of gas chamber |

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.