Packed Bed Absorber

Problem Statement:

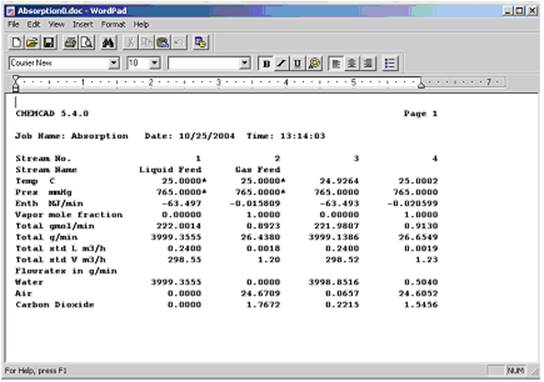

A gas mixture of air (20 L/min) and carbon dioxide (4.5 mol %) is to be absorbed by water (4 L/min). The absorber is a packed column. The column has an inner diameter of 80 mm, and a packed height of 1.27 m. The packing material consists of dumped 3/8” Raschig rings. Water enters the absorber from the top at 25 oC and 765 mmHg and the gas feed enters from the bottom at the same temperature and pressure as those of water. Simulate this absorber in CHEMCAD and determine the composition of the gas leaving the absorber.

Procedure:

Step 1: Creating the flow sheet

Step 2: Entering the components and formatting engineering units

Step 3: Entering the feed stream composition

Step 4: Entering the absorber specs

Step 5: Running the simulation and retrieving the results

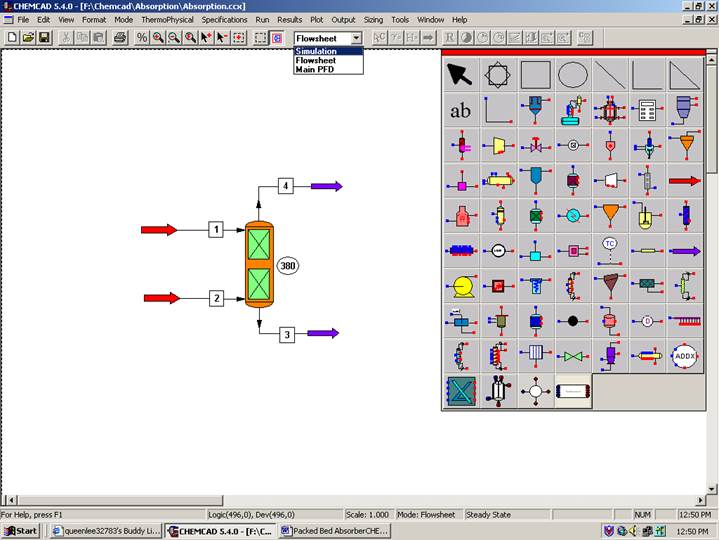

Select and click SCDS column #6 (right click on the regular SCDS icon to find the icon representing this model), and then select 2 feed and 2 product icons on the workspace. Connect the icons appropriately using Stream. Click once on the menu bar to switch the simulation mode from Flowsheet to Run Simulation.

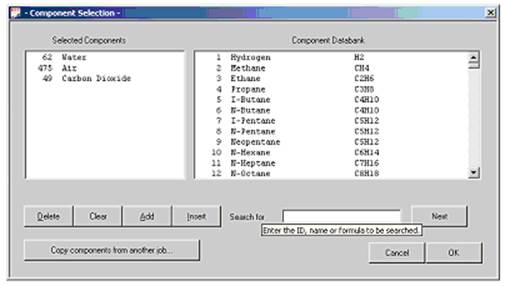

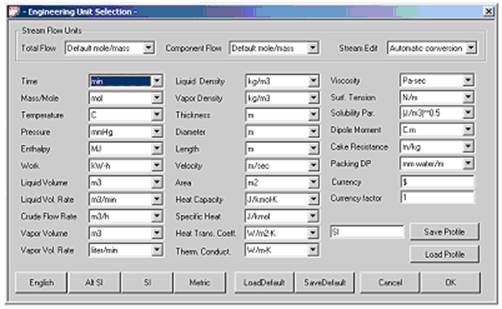

Go to the Thermophysical on the menu bar and click on Components List. Find air, carbon dioxide and water from the CHEMCAD components list and add them to the component list. Go to the Format menu and click on Engineering Units and select the desired units for such properties as temperature, pressure etc. Click OK to continue.

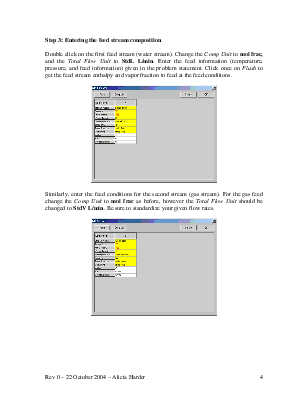

Step 3: Entering the feed stream composition

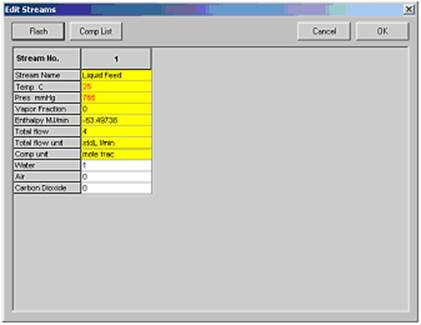

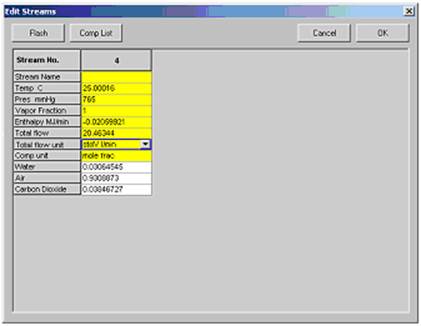

Double click on the first feed stream (water stream). Change the Comp Unit to mol frac, and the Total Flow Unit to StdL L/min. Enter the feed information (temperature, pressure, and feed information) given in the problem statement. Click once on Flash to get the feed stream enthalpy and vapor fraction in feed at the feed conditions.

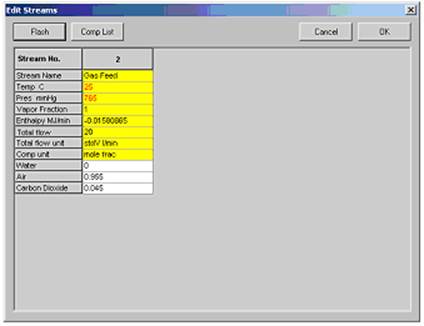

Similarly, enter the feed conditions for the second stream (gas stream). For the gas feed change the Comp Unit to mol frac as before, however the Total Flow Unit should be changed to StdV L/min. Be sure to standardize your given flow rates.

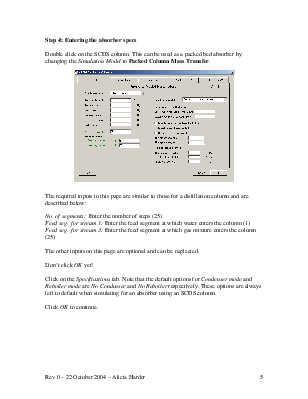

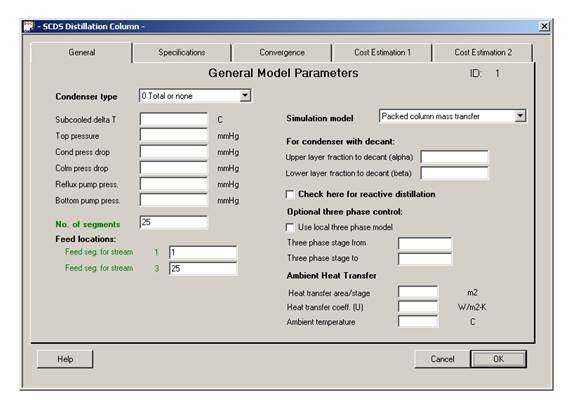

Double click on the SCDS column. This can be used as a packed bed absorber by changing the Simulation Model to Packed Column Mass Transfer.

The required inputs in this page are similar to those for a distillation column and are described below:

No. of segments: Enter the number of steps (25)

Feed seg. for stream 1: Enter the feed segment at which water enters the column (1)

Feed seg. for stream 3: Enter the feed segment at which gas mixture enters the column (25)

The other inputs on this page are optional and can be neglected.

Don’t click OK yet!

Click on the Specifications tab. Note that the default options for Condenser mode and Reboiler mode are No Condenser and No Reboiler respectively. These options are always left to default when simulating for an absorber using an SCDS column.

Click OK to continue.

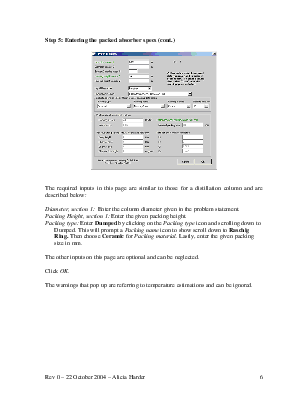

Step 5: Entering the packed absorber specs (cont.)

The required inputs in this page are similar to those for a distillation column and are described below:

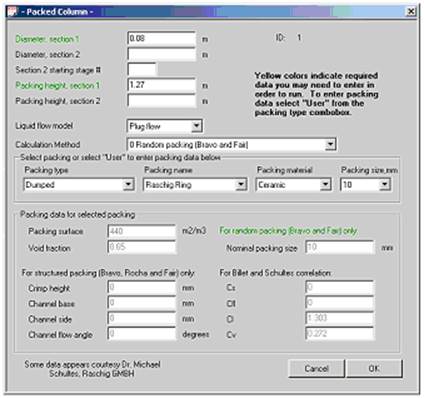

Diameter, section 1: Enter the column diameter given in the problem statement.

Packing Height, section 1: Enter the given packing height.

Packing type: Enter Dumped by clicking on the Packing type icon and scrolling down to Dumped. This will prompt a Packing name icon to show scroll down to Raschig Ring. Then choose Ceramic for Packing material. Lastly, enter the given packing size in mm.

The other inputs on this page are optional and can be neglected.

Click OK.

The warnings that pop up are referring to

temperature estimations and can be ignored.

Step 5: Running the simulation and retrieving the results:

Now the simulation is ready to be run. Click once on R to run the simulation. Alternatively, one can run the simulation by clicking on Run on the menu bar and selecting Run all. The status of the simulation can be found at the bottom left hand corner of the screen. The message, Run Finished, appears if the run is successfully completed. The product stream properties can be found by double clicking the product streams.

You can change your Comp unit icon to specify the way in which you want your results to be viewed.

Also, you can click on the Results tab in the tool bar and click on Set Flow Units to change the way your results are viewed.

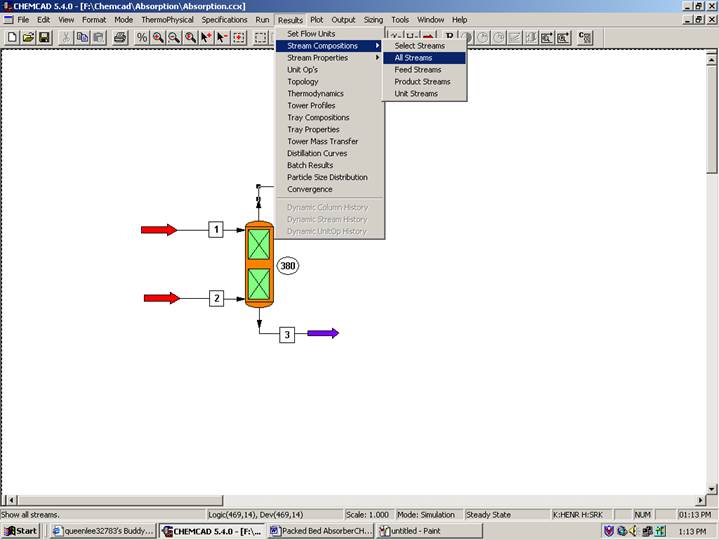

To view all stream results, click on the Results button in the tool bar, scroll down to Stream Compositions, and choose All Streams.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.