AIR TO FUEL RATIO AND TORQUE CONTROL

OF SPARK IGNITION ENGINES

Dmitry N. Gerasimov

Department of Control Systems and informatics

Saint Petersburg State University of Information Technologies, Mechanics and Optics

Sablinskaya 14, Saint Petersburg, 197101, RUSSIA

Tel: 8 (812) 595-41-28, E-mail: gerasimovdn@mail.ru

Abstract: In this paper two main problems of control of spark ignition engines are treated: stabilization of air to fuel ratio with the purpose of full fuel combustion and decreasing exhaust emissions, and torque regulation that is used for maintenance of engine speed. Synthesis of control algorithms is based on nonlinear and adaptive control technique. The algorithms are constructed with the use of adequate mathematical model of the engine that describes consequence of transformation of control signals into regulated variables.

1. Introduction and Problem Statement

Modernization of spark ignition (SI) engines connected with both improvement of engine construction and successful design with implementation of control systems. The development of such control systems is very difficult due to the multiplicity of control systems, operating modes, performance requirements and constraints, uncertainty parameters of the engine. As a result problems of the engine control are actual and require particular investigations.

In the modern automobiles, the driver can act on the throttle by means of the throttle position drive that changes angle. Thus driver controlling car velocity modifies engine torque. In these conditions, a rapid change of throttle angle can result in inadequate air to fuel ratio control. The main reason of such behavior is in relatively slow changing of fuel evaporation parameters (for instance time of evaporation) in the intake manifold. Moreover these parameters cannot be measured directly that motivates necessity of using adaptive and nonlinear control technique. Thus one more problem of coordinated air to fuel ratio control in conditions of uncertainty takes place in synthesis of control system.

In recent years the problem of torque regulation has been devoted a lot of papers. And here it is possible to mention works [1] (speed-gradient method), [2] (linear system identification methods).

The solution of problem of air to fuel ratio control has been proposed in works [2, 3, 4] with the use of Kalman filter estimation and sliding mode approaches. The main lack of such approaches is necessity of knowledge about the physical processes like wall-wetting dynamic parameters (a priori information).

In this paper a solution of coordinated air to fuel ratio and torque regulation of SI engines in terms of adaptive and nonlinear methods of automatic control with compensation of unknown dynamic is proposed. Thus the problems of control are to be solved conclude in the following:

regulation of the engine torque with the purpose of maintenance crankshaft (and automobile) speed;

stabilization of air to fuel ratio in cylinders on stoichiometric (14,7 for gasoline) value with compensation both changing of throttle angle and fuel evaporation dynamic. The main purpose of stabilization is to decrease undesirable exhaust emissions of CO2 CO and NOx.

Realization

of control algorithm is possible in SI engines equipped with microprocessor

systems. It is known such engines are a highly complex systems consisting of

several subsystems that describe different chemical, mechanical and

thermodynamical processes. Some of these processes are cyclical. To provide

suitable solution of posed problems the model in terms of averaged for one

cycle variables (so-called mean-value model) is proposed [4, 5, 6, 7]. This

model is to be designed to describe consequence of transformations of the input

signals (throttle angle![]() and mass flow rate of fuel from

injector

and mass flow rate of fuel from

injector ![]() ) into regulated variables (air to fuel

ratio

) into regulated variables (air to fuel

ratio ![]() and indicated torque

and indicated torque ![]() ). It consists of the following subsystems

[4, 7]

). It consists of the following subsystems

[4, 7]

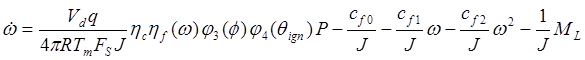

1. Crankshaft dynamic subsystem:

(1)

(1)

where ![]() is the

crank speed [rad/sec],

is the

crank speed [rad/sec], ![]() is the displacement volume

is the displacement volume ![]() ,

, ![]() is the

ideal gas constant

is the

ideal gas constant ![]() ,

, ![]() is the

heating value of the fuel,

is the

heating value of the fuel, ![]() is the intake manifold

temperature

is the intake manifold

temperature ![]() ,

, ![]() is the

stoichiometric air-to-fuel ratio (14,7 for gasoline),

is the

stoichiometric air-to-fuel ratio (14,7 for gasoline), ![]() is

the rotational moment of inertia

is

the rotational moment of inertia ![]() ,

, ![]() is the cylinder charge efficiency [%],

is the cylinder charge efficiency [%], ![]() is the conversion efficiency,

is the conversion efficiency, ![]() ,

, ![]() are static functions of

fuel to air ratio in cylinders

are static functions of

fuel to air ratio in cylinders ![]() and spark angle

and spark angle ![]() ,

, ![]() is the air pressure in

the intake manifold [Pa],

is the air pressure in

the intake manifold [Pa], ![]() ,

, ![]() ,

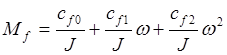

, ![]() are coefficients of

engine losses (

are coefficients of

engine losses ( is torque

of loses),

is torque

of loses), ![]() is the external

load torque [N×m].

is the external

load torque [N×m].

This equation is derived from Newton's law.

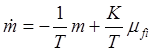

2. Fuel evaporation dynamic in the intake manifold. Subsystem describes evaporation process of fuel film in the manifold [6].

(2)

(2)

where ![]() is the mass flow rate of

fuel film [kg/sec],

is the mass flow rate of

fuel film [kg/sec], ![]() is the

mass flow rate of fuel injected into cylinders [kg/sec],

is the

mass flow rate of fuel injected into cylinders [kg/sec], ![]() is the time constant of

evaporation process [sec],

is the time constant of

evaporation process [sec], ![]() is the

part of fuel which is injected into cylinder directly.

is the

part of fuel which is injected into cylinder directly.

Remark 1: It is necessary to note that

neither ![]() nor

nor ![]() can not be measured

directly. Moreover these parameters are variable due to changing temperature

and pressure of air and fuel. Therefore this model is parametrically uncertain,

that motivates the use of adaptive control technique in stabilization of air to

fuel ratio.

can not be measured

directly. Moreover these parameters are variable due to changing temperature

and pressure of air and fuel. Therefore this model is parametrically uncertain,

that motivates the use of adaptive control technique in stabilization of air to

fuel ratio.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.