On the basis of empirical data the fuzzy model of cutting process, intended for control of cutting force, is identified.

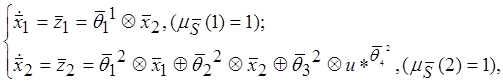

(4)

(4)

![]() ,

,

where

![]() - output coordinate (cutting force),

- output coordinate (cutting force),

![]() - state vector coordinates,

- state vector coordinates,

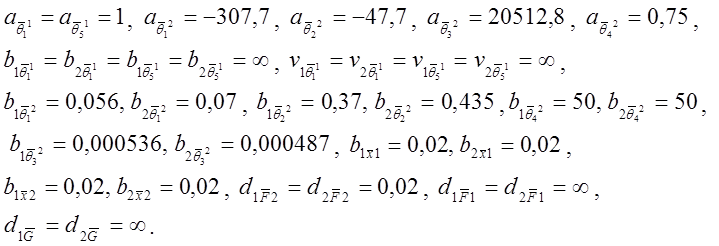

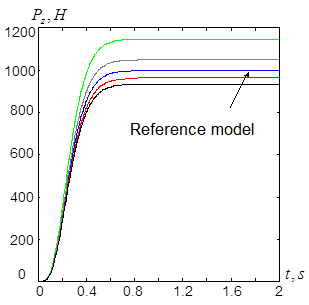

Calculation on model is made and graphics of transients are received (figure 1). Apparently, variations of cutting force change within the limits of one technological transition under usual technological conditions can make 40 % and more.

Figure 1 – Result of calculations by fuzzy dynamic model

Therefore laws of technical objects control such as technological operations should minimize a mismatch between reference variables of a condition and the most probable estimated, and also to reduce prior uncertainty about object due to use of the operative information from means of measurement and adaptation to current technological conditions.

Requirements, stated above, are satisfied by adaptive control systems with robust properties.

Synthesis of a control system is executed with application of one of adaptive robust algorithms - algorithm of a speed gradient with obvious reference model. Thus the signal of control is formed on the basis of the whole set of values of variables of a condition, which is possible at variations of cutting process behaviour. For improvement of quality and accuracy of control systems transients the algorithm of operative decision-making at the choice of a compromise operating signal is built in algorithm of control.

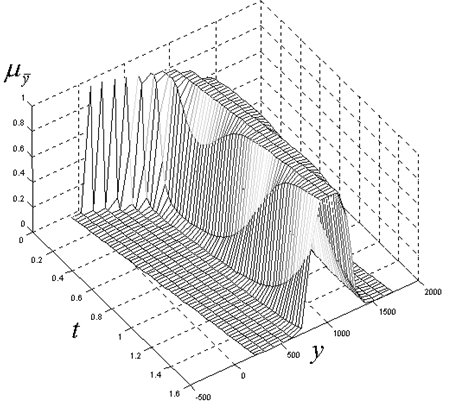

On the poster the block diagram of a control system is shown.

Figure 2 – Adaptive control system based on fuzzy dynamic model

Synthesis of the law of control is

executed for linearized model of cutting process. The initial information is

the model of generalized adjusted object, value of factors in fuzzy sets and

fuzzy functions, and also reference model: ![]() , generated on the basis of the set parameters of quality of control,

where

, generated on the basis of the set parameters of quality of control,

where ![]() - setting influence of system. Generalized

adjusted object (named plant on figure 2) represents a subsystem of

stabilization of cutting force and includes cutting process, a lathe, the

electric drive of feed, the force sensor, the device of numerical program

control, force integral regulator.

- setting influence of system. Generalized

adjusted object (named plant on figure 2) represents a subsystem of

stabilization of cutting force and includes cutting process, a lathe, the

electric drive of feed, the force sensor, the device of numerical program

control, force integral regulator.

The signal of control from an output of an

adaptive regulator u=Pzз, acts on generalized adjusted object as a setting signal. Two variants

of criteria are used for synthesis of adaptive control system. The first

criterion ![]() means minimization of an average deviation

of variables of state vector of real behavior from the standard. The second

criterion

means minimization of an average deviation

of variables of state vector of real behavior from the standard. The second

criterion ![]() shows dispersion of target variable values

of generalized adjusted object.

shows dispersion of target variable values

of generalized adjusted object.

3. SIMULATION AND CONCLUSION

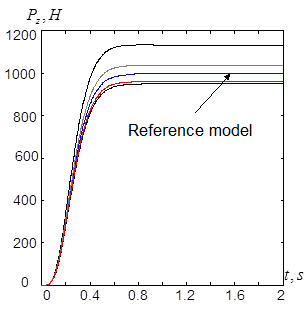

On figure 3 transients in the developed adaptive control systems are shown. The most unfavorable mode from the point of view of loadings on cutting tool - process of incision was considered. Thus change of model’s transfer factor reached 10 times and more.

a) b)

Figure 3 – Result of simulation

Opportunity of choice a compromise control

signal u=Pzз according to criterion of quality![]() (figure 3a) reduces an average deviation of condition

vector variables of real process from the standard by 15 %, and by criterion

(figure 3a) reduces an average deviation of condition

vector variables of real process from the standard by 15 %, and by criterion ![]() (figure 3b) reduces dispersion of possible values Pz

on the average by 20 %. At the same time dynamics of change of the longitudinal

minute feed, in synthesized system, satisfies to possible restrictions.

(figure 3b) reduces dispersion of possible values Pz

on the average by 20 %. At the same time dynamics of change of the longitudinal

minute feed, in synthesized system, satisfies to possible restrictions.

4. REFERENCES

[1] Miroshnik I.V., Nikiforov V.O., Fradkov A.L. Nonlinear and adaptive control of complex dynamical systems, St.-Petersburg: Nauka, 2000.

[2] Methods of description, analysis and synthesis of nonlinear control systems/ V.V. Semyonov, A.V. Panteleev, E.A. Rudenko, A.S. Bortakovski: MAI, 1993.

[3] I.F. Mesyagutov, S.G. Goncharova,. Formal description of cutting process for control problems solution. Preprints of 8th International Students Olympiad on Automatic Control, 2000, pp. 41-45.

[4] V.Ts. Zoriktuev, I.F. Mesyagutov, S.G. Goncharova,. Adaptive control system of machining process based on fuzzy dynamic model. Vestnik UGATU №2 (10), v. 5, 2004, pp. 136-144.

Уважаемый посетитель!

Чтобы распечатать файл, скачайте его (в формате Word).

Ссылка на скачивание - внизу страницы.